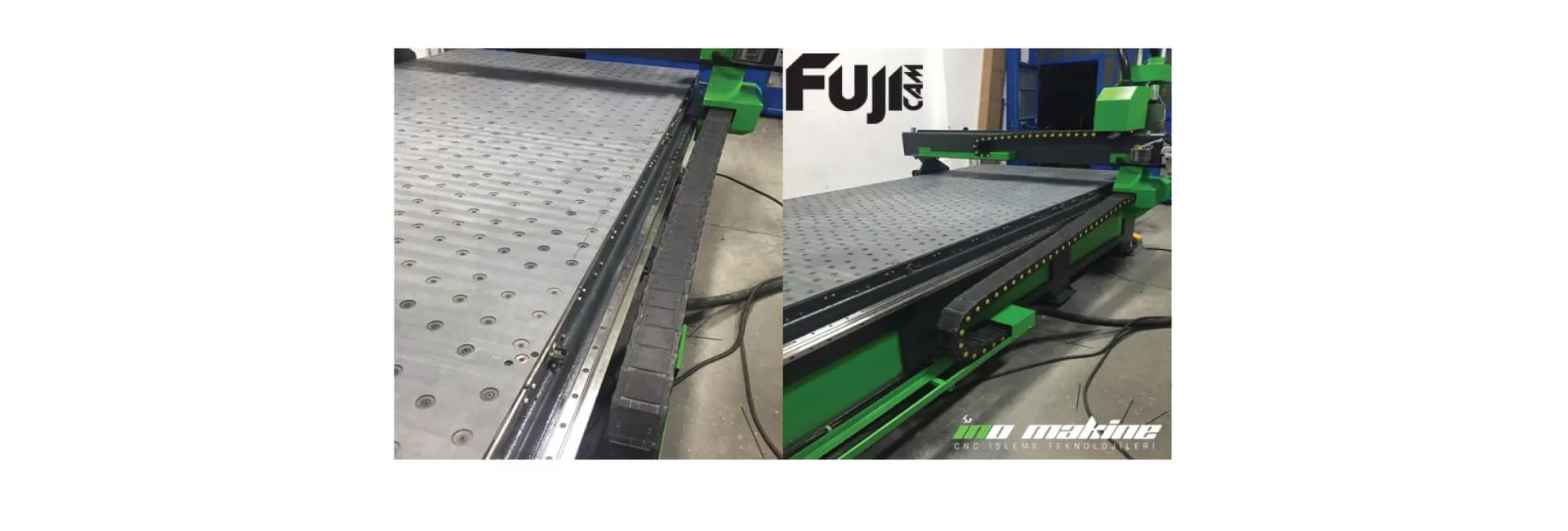

XA 1535 2nd рука CNC композитный обрабатывающий центр

Product Properties

Ино XA 1535 (2-я рука) является самым современным и современным объектом, который работает в области резки и обработки панелей, особенно фасадов производства и применения, а также мастерские, которые делают контракт с ЧПУ резки — калибровки, может обрабатывать все виды пластин — верхнего класса алюминиевых композитных панелей до 3.500 мм. это самый экономичный двойной шпиндель CNC панели обработки центра.

С этим типом центра обработки композитных материалов с ЧПУ мы предоставляем нашим клиентам дополнительную программу CAD-CAM, которая обычно оплачивается как опция, с XA 1535 в качестве стандарта — бесплатно.

Кроме того, комплект швов и фрезерных ножей поставляется вместе с машиной в виде комплекта.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

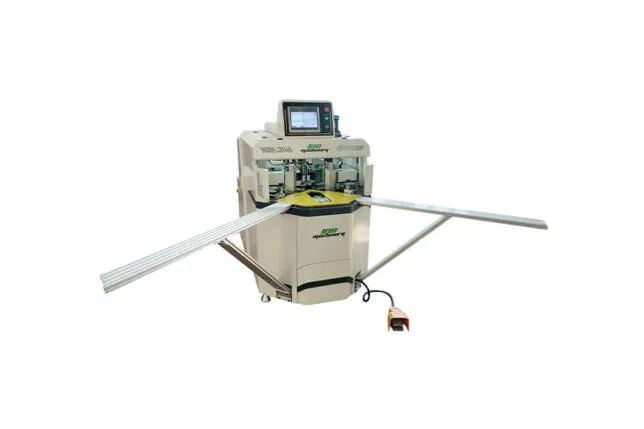

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв