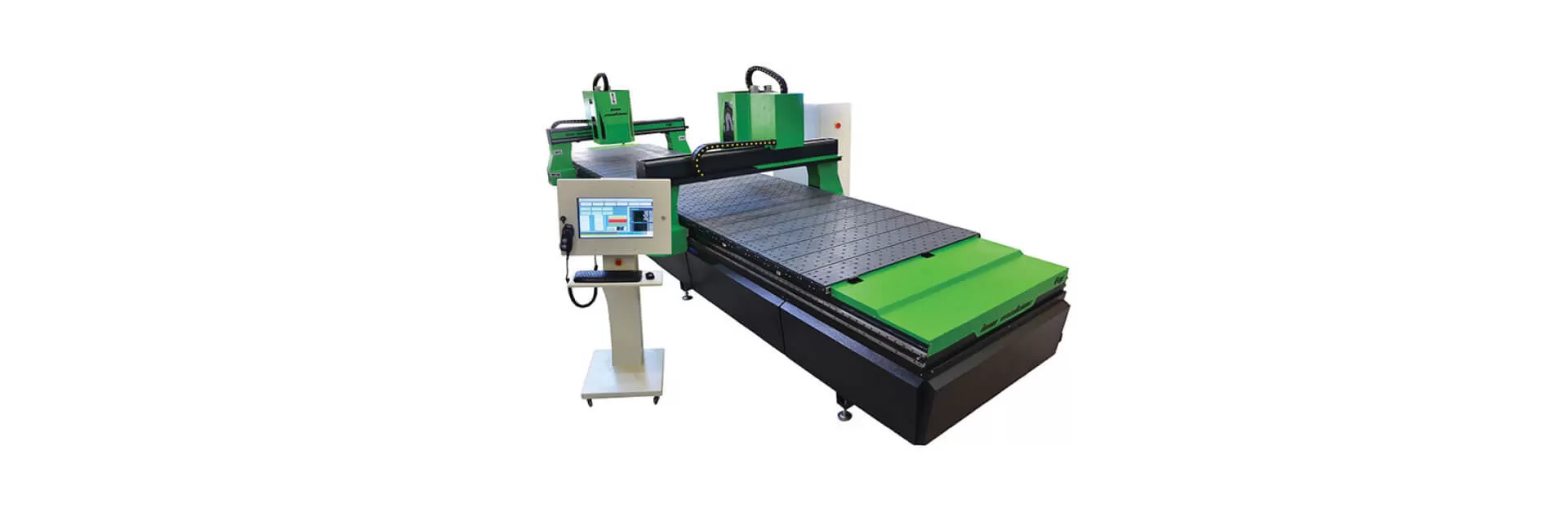

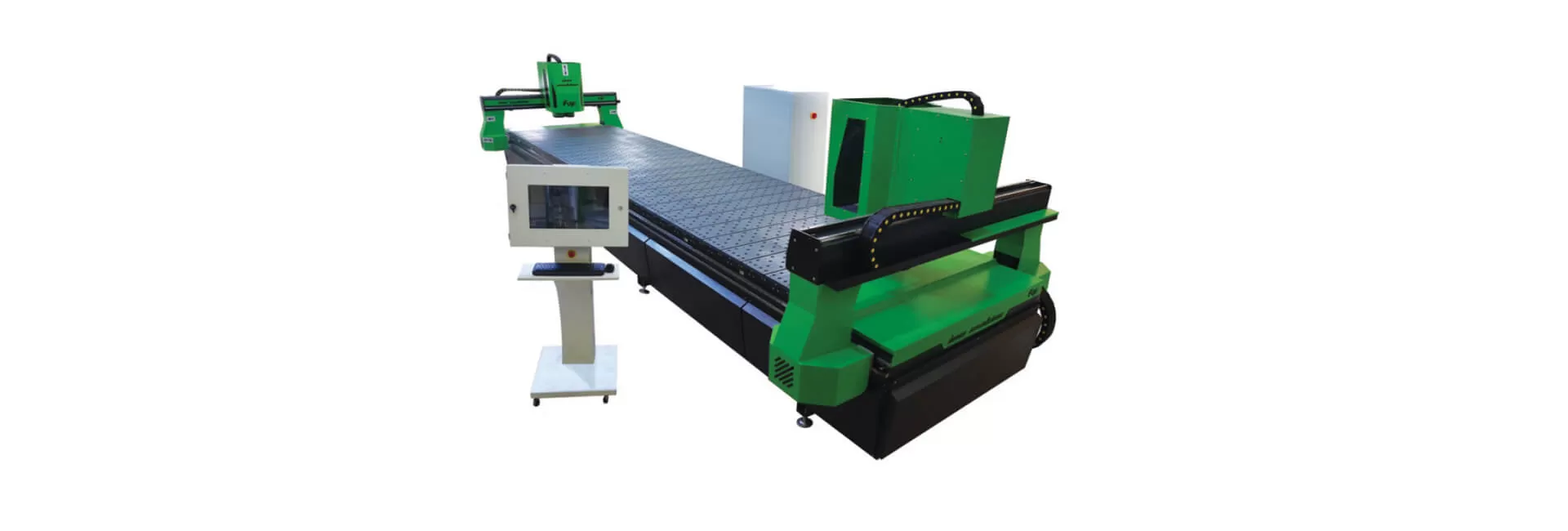

INO XX 9900 двойной мост CNC панели обрабатывающий центр

Product Properties

Это обрабатывающий центр с ЧПУ, где Double Bridge работает на вакуумном столе в то же время.

В зависимости от предпочтений оператора, два моста обрабатывают две отдельные панели одинакового размера, или работают над двумя отдельными проектами, или оба работают над одной деталью.

Они защищены механически и программно. Как и другие наши обрабатывающие центры для панелей, вакуумный стол машины автоматически выбирает вакуумные области в соответствии с размером обрабатываемой пластины и предотвращает ошибки оператора.

В этой модели могут быть предпочтительны либо двойные шпиндели, либо модели шпинделя смены инструмента. Два вакуумных насоса поставляются в стандартной комплектации и назначаются в требуемые отсеки на двух отдельных станциях.

Каждая из 10 пневматических опорных точек на станке управляется с помощью ЧПУ с электрическими клапанами, минимизирующими ошибки оператора.

Profile Machining Software

Он работает с настроенным программным обеспечением для обработки панели.

Наша программа под названием CamBOX обеспечивает большое удобство для чертежного персонала при обработке всех видов пластин. Путем вбрасывания чертежей DXF панелей непосредственно в программу и введения линий обработки на них в качестве различных плоскостей, с помощью программы можно выполнять такие операции, как оптимизация обработки, оптимизация траектории инструмента, оптимизация пластин и определение траектории инструмента.

Размеры отходов на предприятии могут быть введены, и при необходимости может быть составлен список оптимизации со всеми отходами.

Композитная панель, HPL (компактный ламинат) и специальные макросы для алюминиевых листов для строительного сектора доступны.

Main Body

Сварная стальная рама, нормализованная термической обработкой.

Основной корпус машины обрабатывается в 5-осевом обрабатывающем центре с ЧПУ.

Весь корпус окрашен электростатической порошковой краской.

В основном все механические детали обрабатываются в наших собственных обрабатывающих центрах с ЧПУ или обрабатываются на литой материал.

В механической конструкции используются не только сталь и алюминий; в то же время детали для литья из стекловолокна также используются для уменьшения веса технологического моста и придания машине более эстетического вида.

Spindles

Версии с двойным шпинделем оснащены двумя головками шпинделя с держателем инструмента ER-32 мощностью 5,5 кВт 18 000 об/мин и двумя инструментами работают последовательно или имеют шпиндель ISO 30 24 000 об/мин с 7,5 кВт, интегрированный на мосту и автоматически переключать инструменты с помощью 6-инструментального меняющегося магазина, установленного под этим мостом.

Electrical Box and Controller Terminal

Электрическая панель расположена отдельно от машины на колесах.

Принудительный вентилятор с охлаждением в стандартной комплектации, опционально с охлаждением с помощью кондиционера для жаркого климата.

Терминал управления также выполнен в виде отдельного киоска, он соединен с электрической панелью 5-метровым кабелем.

Благодаря этому позиционированию оператор может легко добраться до любой точки машины и может следовать за машиной из любого места во время обработки.

На управляющем терминале имеется Промышленный ПК и его дисплей, кнопка включения/выключения станка, кнопки перемещения осей +/- , потенциометр кнопки управления темпом выполнения станка, а также клавиатура и мышь.

Axis features

Ось X движется по зубчатым, шестерневым и линейным полозьям с помощью двух серводвигателей и планетарных редукторов. Скорость по оси составляет 80 м./мин. С помощью Y-оси Servo Motor и Planetary редуктор, движение кравели на протекторе, шестерни и линейные слайды. Осевая скорость 65 м./минОсь Z движется с редукционной муфтой 1/1 на 25-роликовом 25-шнековом валу.Осевая скорость 25 м./мин.

Standard Equipment

Автоматическое открытие и закрытие вакуумных зон в соответствии с размером листа, который будет обрабатываться с помощью управления с ЧПУ.

Десять пневматических опорных точек.305 м3 вакуумный насос.

7,5 кВт 24 000 об/мин шпинделя ISO 30 и 6-пакетный магазин смены инструмента или 5,5 кВт 18 000 об/мин двойной шпиндель.

Смазка осевых подшипников.

Программное обеспечение 3D CAD-CAM.

21-дюймовая сенсорная панель.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

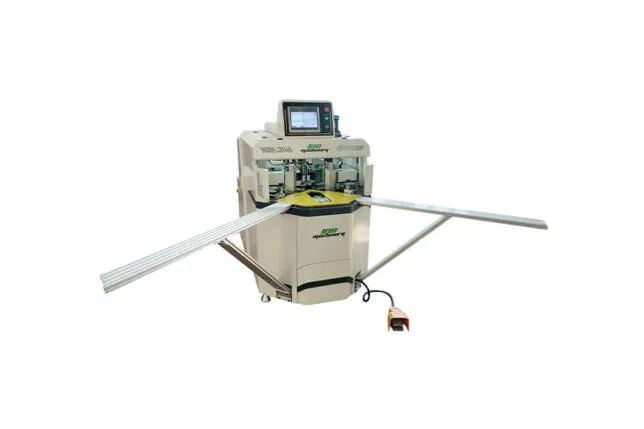

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв