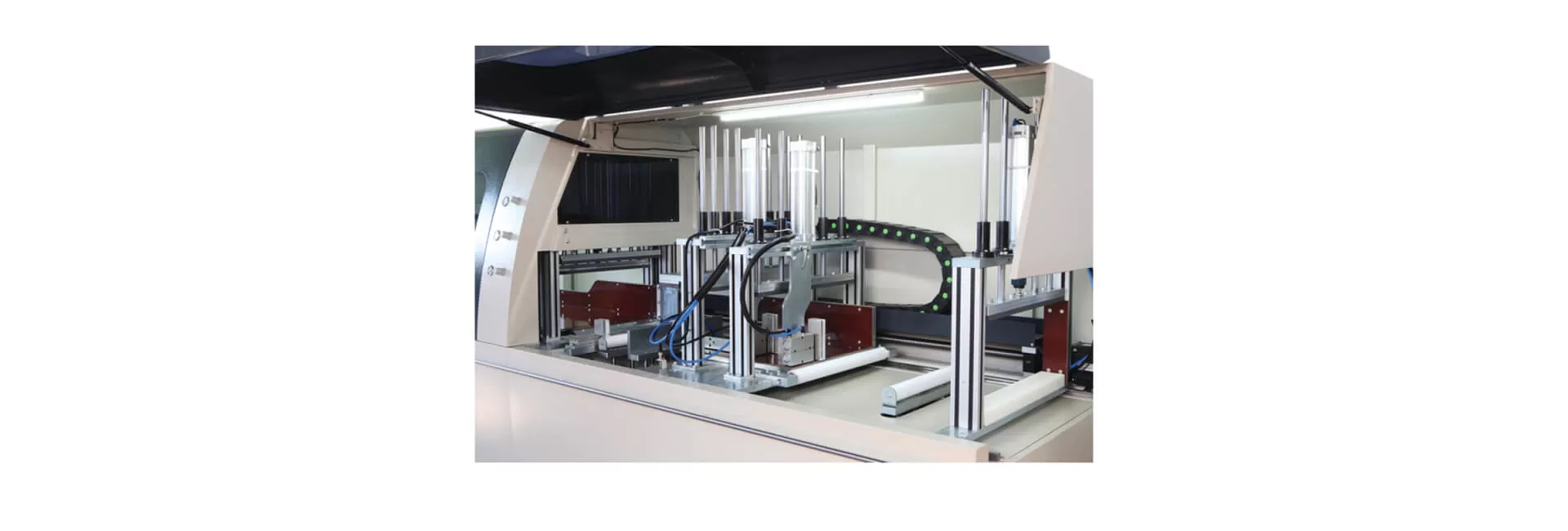

AS 499 Автоматическая режущая пила для промышленных профилей

Product Properties

Это автоматический станок для резки с радиальной пилой, специально разработанный для резки крупных алюминиевых профилей.

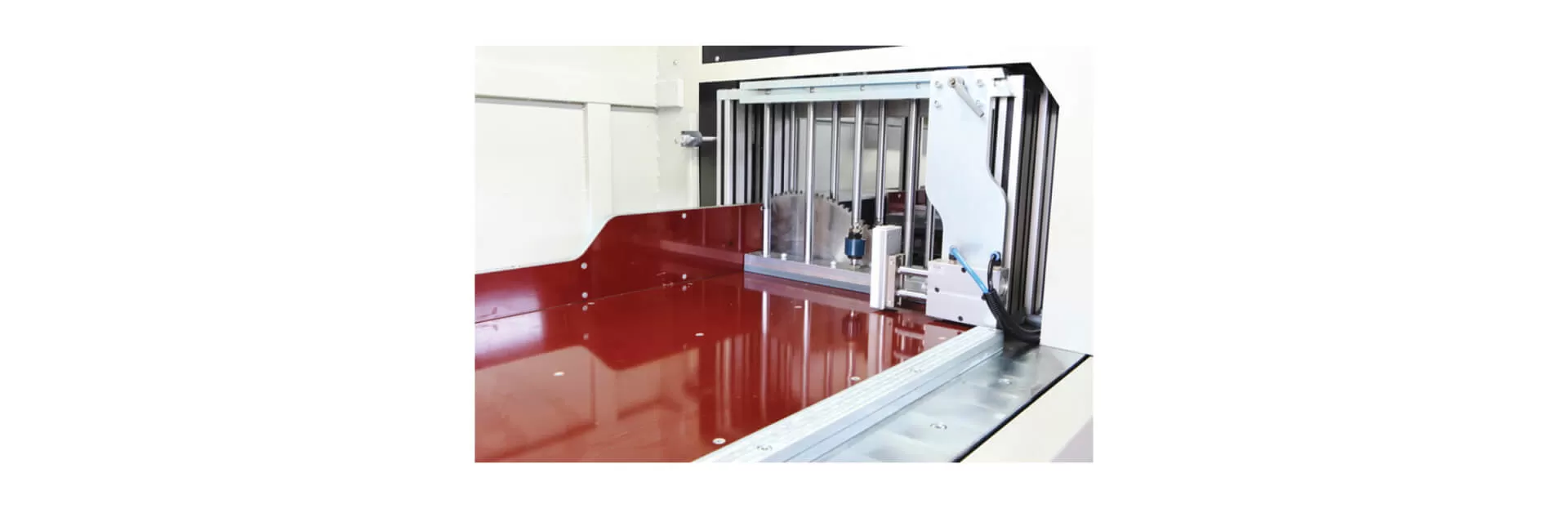

Профили загружаются в машину на длине 6 метров, машина автоматически подает их к механизму серводвигателя в коротких размерах, данных через управление PLC и разрезает их с радиальной движущейся пилой, связанной с механизмом серводвигателя и стол открывается, пока пила возвращается, чтобы уменьшить метки на поверхности сечения.

К станку прилагается стандартная пила диаметром 700 мм. По желанию можно подключать пилы различных размеров до 350 мм. Имеется огромный режущий мотор мощностью 11 кВт, который можно регулировать от 0 до 4000 об/мин в зависимости от размера пилы. В зависимости от толщины стенки разрезаемого профиля и степени твердости материала скорость подачи пилы можно регулировать с панели управления; можно запоминать в соответствии с типом профиля.

В соответствии с размерами профиля выемки фиксирующее положение режущей пилы и точка, в которой режущие концы регулируются в соответствии с минимальной потерей времени благодаря механизму сервомотора пилы; запоминается.

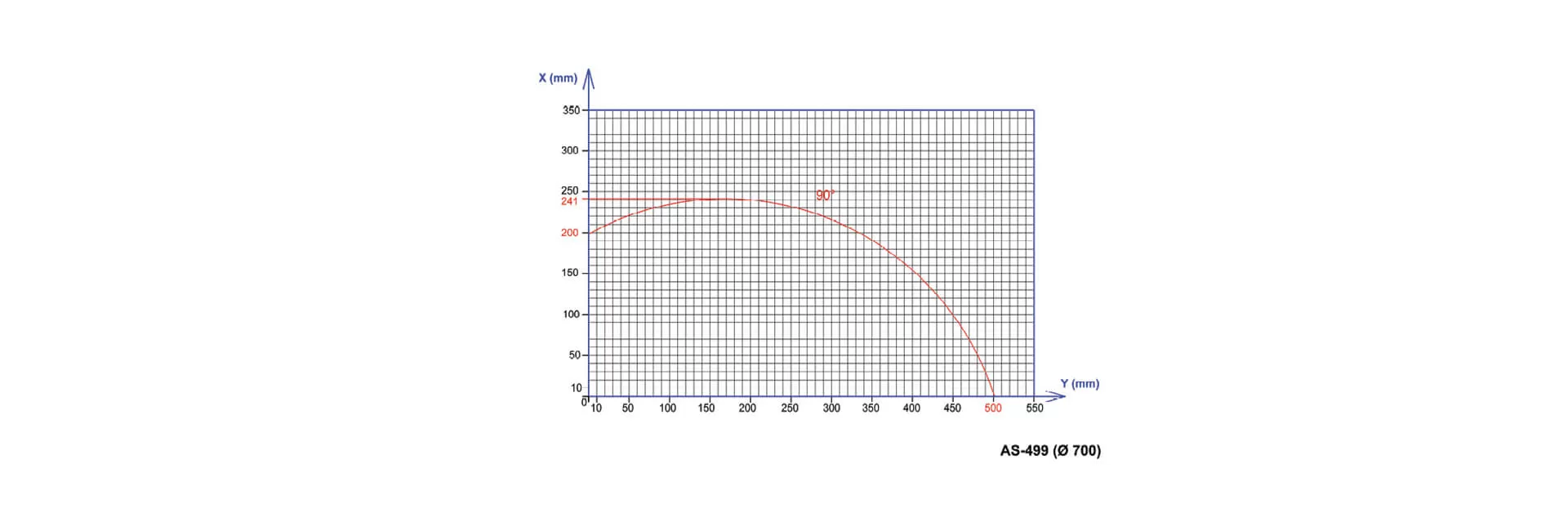

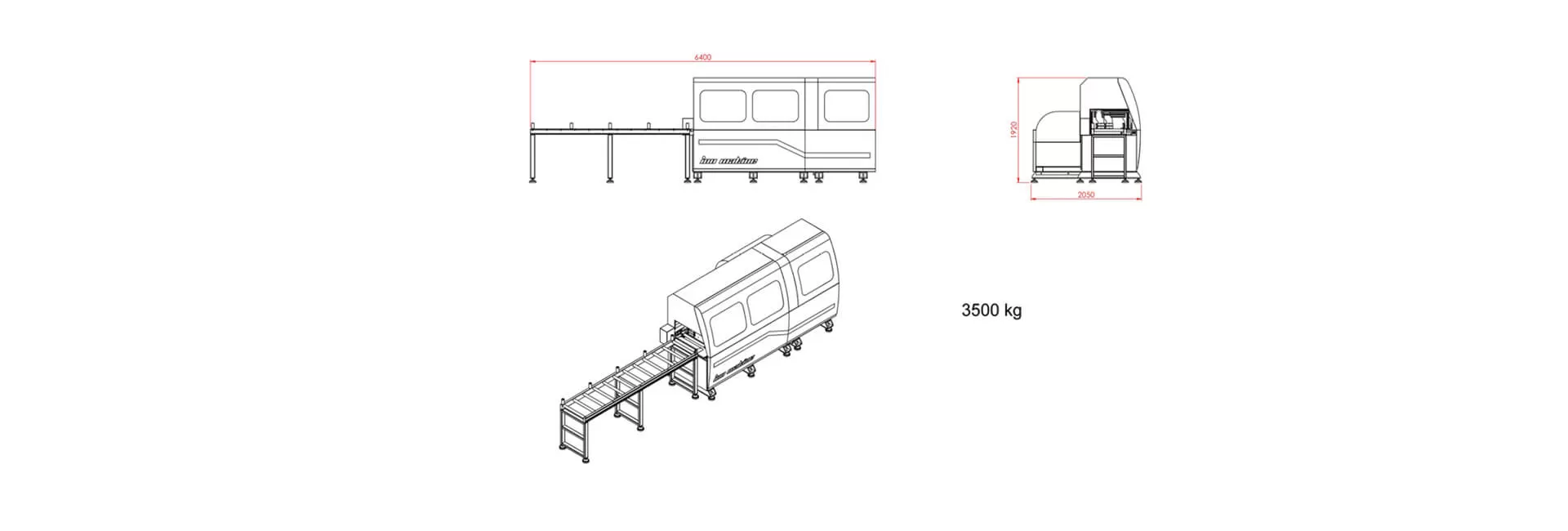

Максимальная длина системы скольжения с сервоприводом составляет 1200 мм. Самая большая ширина, которую система скольжения сервопилки может вырезать с помощью пилы 700 см, составляет 500 мм. Существует 9 различных блоков сжатия профиля, что приводит к сжатию профиля и высочайшему уровню точности.Допуски резания составляют 0,1 мм.Рядом с машиной 3-метровый конвейер, защитная крышка машины и кнопки аварийной остановки являются стандартным оборудованием для подачи профилей.

Profile Machining Software

Программное обеспечение для управления резкой профиля управляется на станке с помощью сенсорной панели.

Станок приводится в действие путем ввода длины профиля и размера нарезки, которые должны быть вырезаны на экране.

В соответствии с типом профиля, длины резания могут быть записаны в память машины.

Main Body

Сварной стальной каркас, нормализованный путем тепловой обработки.

Основной корпус машины подвергается механической обработке в 5-осевом обрабатывающем центре с ЧПУ.

В основном все механические части обрабатываются в наших собственных обрабатывающих центрах с ЧПУ или обрабатывается на литой материал.

В процессе проектирования наша команда дизайнеров придает первостепенное значение простоте использования и эргономичности машин операторов.

В механической структуре используются не только сталь и алюминий; в то же время детали из стекловолокна также используются для уменьшения веса обрабатывающего моста и придания машине более эстетического вида.

Standard Equipment

10,2-дюймовая сенсорная панель TFT-LCD.

Система управления ПЛК + 99999 ПК режущая память.

700 мм пила 11,0 кВт, 4000 об/мин пильный двигатель.

Возможность регулировать скорость пилы с пульта управления от 0-4.000 об/мин с помощью сервоинвертора.

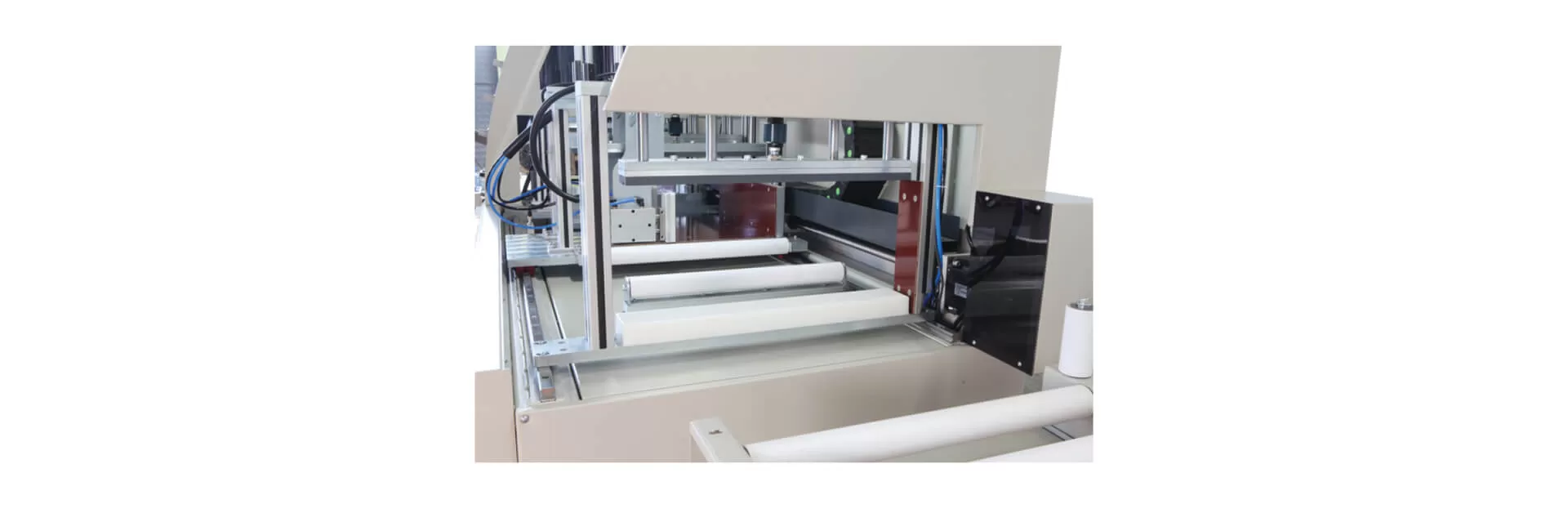

Автоматическое охлаждение пилы с помощью блока смазки распылением.

Движение радиальной (уходящей) пилы осуществляется серводвигателем, после окончания резки стол открывается, профиль отводится назад, пила поворачивается обратно пустой.

Защитная крышка с ручным перемещением.

4 узла зажима, состоящие из горизонтальных и вертикальных узлов зажима профиля и узлов сжатия вертикальных и яхт по обеим сторонам пильного бункера.3 метра.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

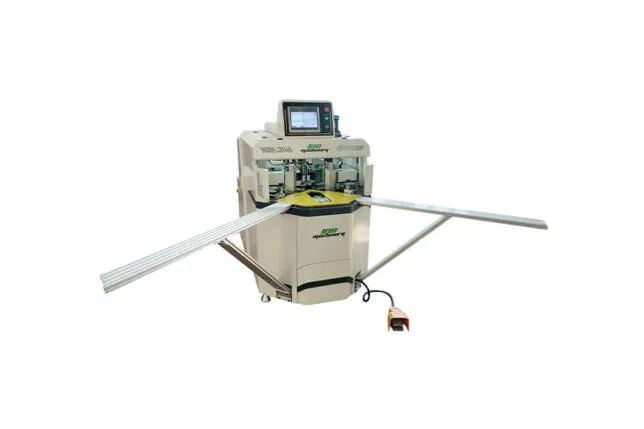

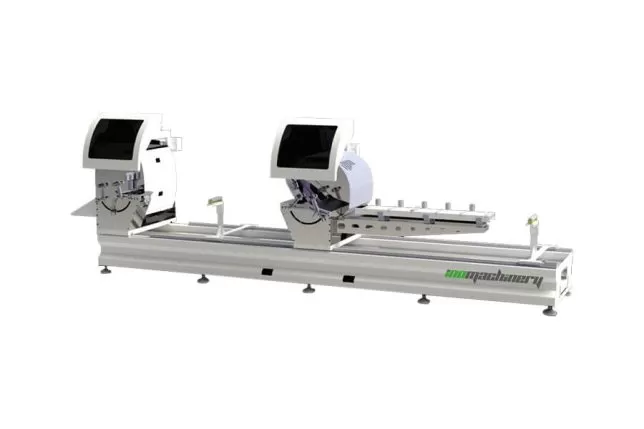

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв