AS 425 45 Одинарный Митре Пила

ALU

450mmОдиночная пила INO | Алюминиевый станок для пилы для резки

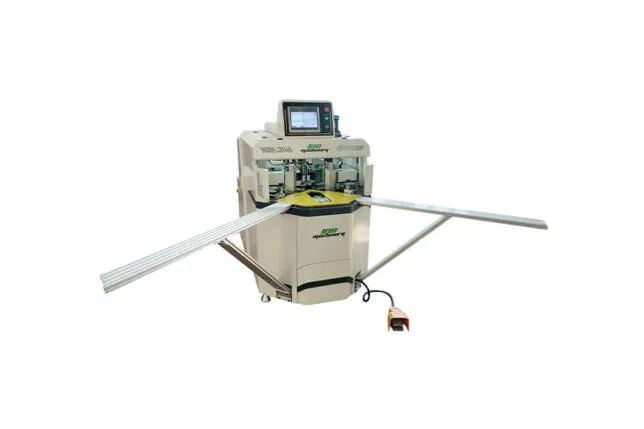

Станок для резки алюминиевых профилей углом 0-135 градусов и пилообразной лентой 450 мм. Пильный станок снабжен гидропневматическим цилиндром и электродвигателем мощностью 3 кВт со скоростью вращения 3000 об/мин. Машина имеет 3 метра ручную систему измерения в стандартной комплектации; в этом видео опциональная 6-метровая система измерения подключена. Охлаждающая жидкость распыленного тумана, автоматическое открытие и закрытие защитного чехла с пневматическим поршнем, передвижная задняя ограждение и подающий роллер-конвейер являются стандартным оборудованием.

Product Properties

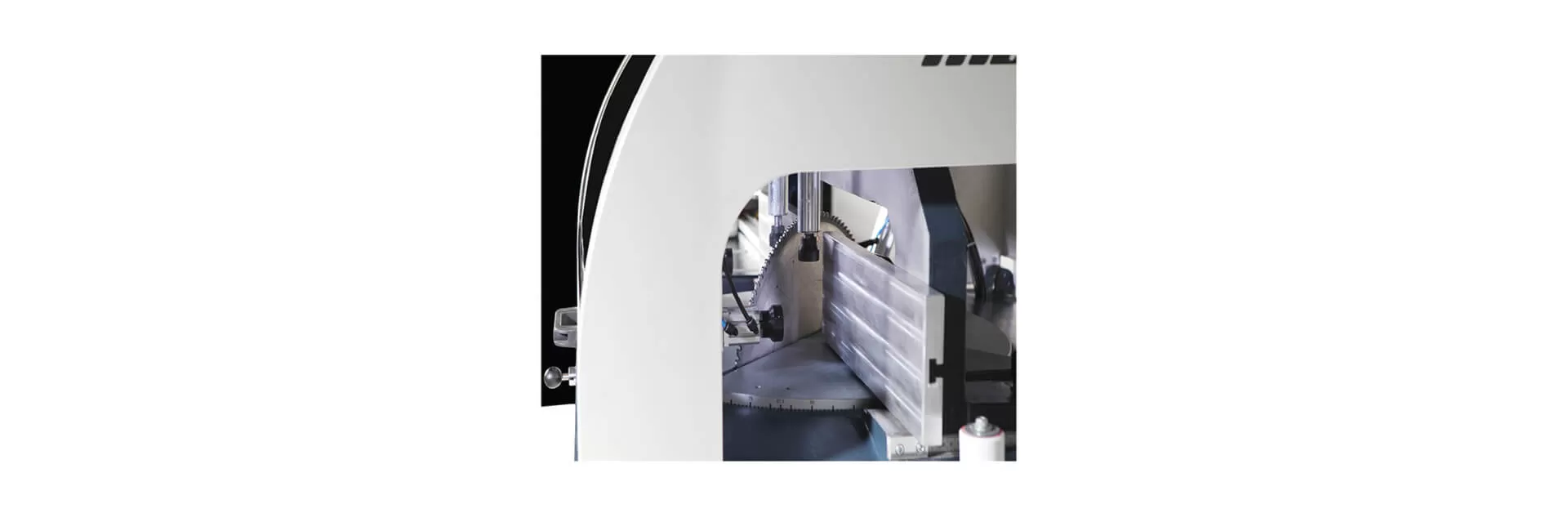

Это одноголовочный режущий станок с 450 мм пилой, выходящей из днища.

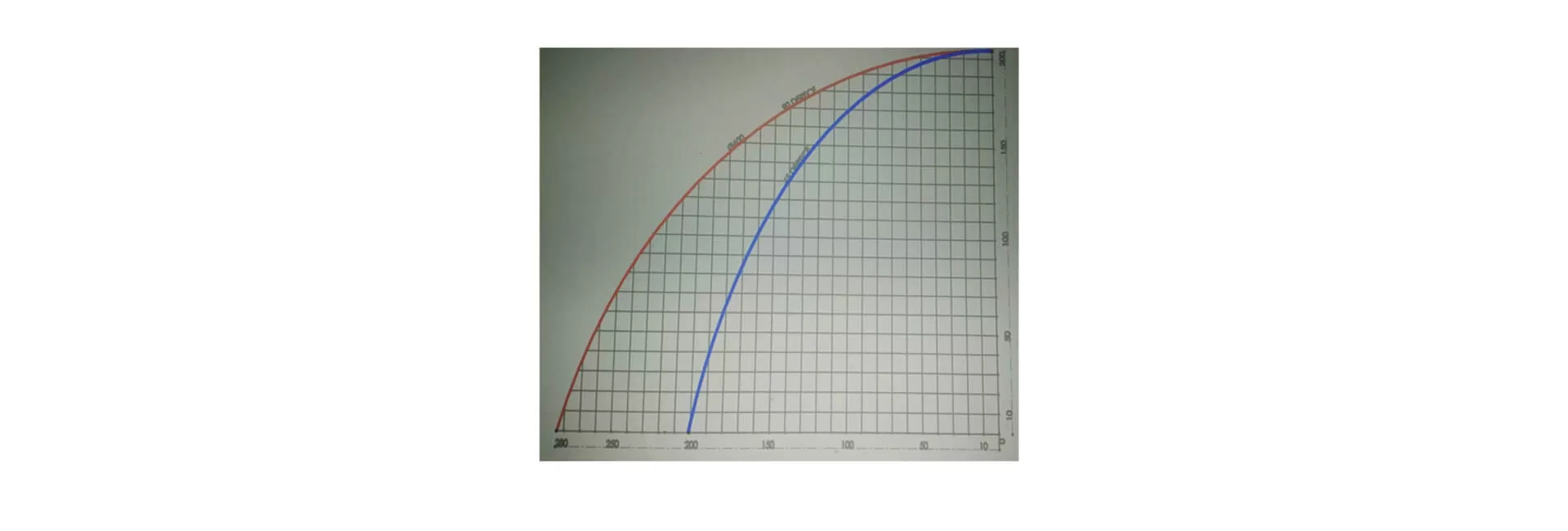

Стол, из которого выходит пила, перемещается вручную между 0-135 градусами вправо и влево.0 градусами, имеет закрепленный механизм ангуляции, который закрепляется на месте под 15 и 45 градусами с обеих сторон.

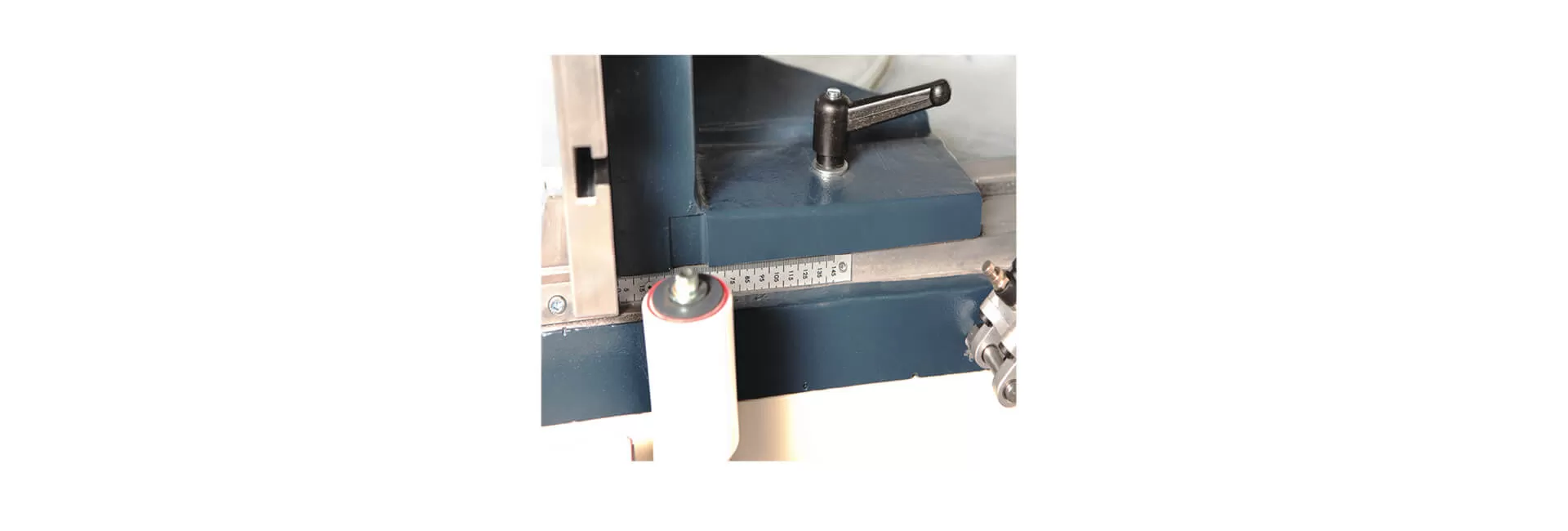

При движении задней подложки до 100 мм профили различной ширины можно срезать или косить при нулевом градусе.

Двигатель мощностью 1,5 кВт раскручивался при 2800 оборотах в минуту.

Двойные пилы поднимаются вверх, когда оператор держит обе руки на станке. Защитная крышка открывается и закрывается вручную, и благодаря выключателю защиты двигатель не запускается, когда крышка открыта.

Main Body

Сварной стальной каркас, нормализованный путем тепловой обработки.

Основной корпус машины подвергается механической обработке в 5-осевом обрабатывающем центре с ЧПУ.

Все тело окрашено электростатической порошковой краской.

В основном все механические детали обрабатываются в наших собственных обрабатывающих центрах с ЧПУ или обрабатываются на литом материале.

В процессе проектирования наша команда дизайнеров придает первостепенное значение простоте использования и эргономике машин операторов. В механической конструкции используются не только сталь и алюминий; в то же время детали из стекловолокна также используются для снижения веса обрабатывающего моста и придания машине более эстетического вида.

Standard Equipment

Управляющая клавиатура, состоящая из кнопок управления.

Система управления ПЛК и ручное управление.

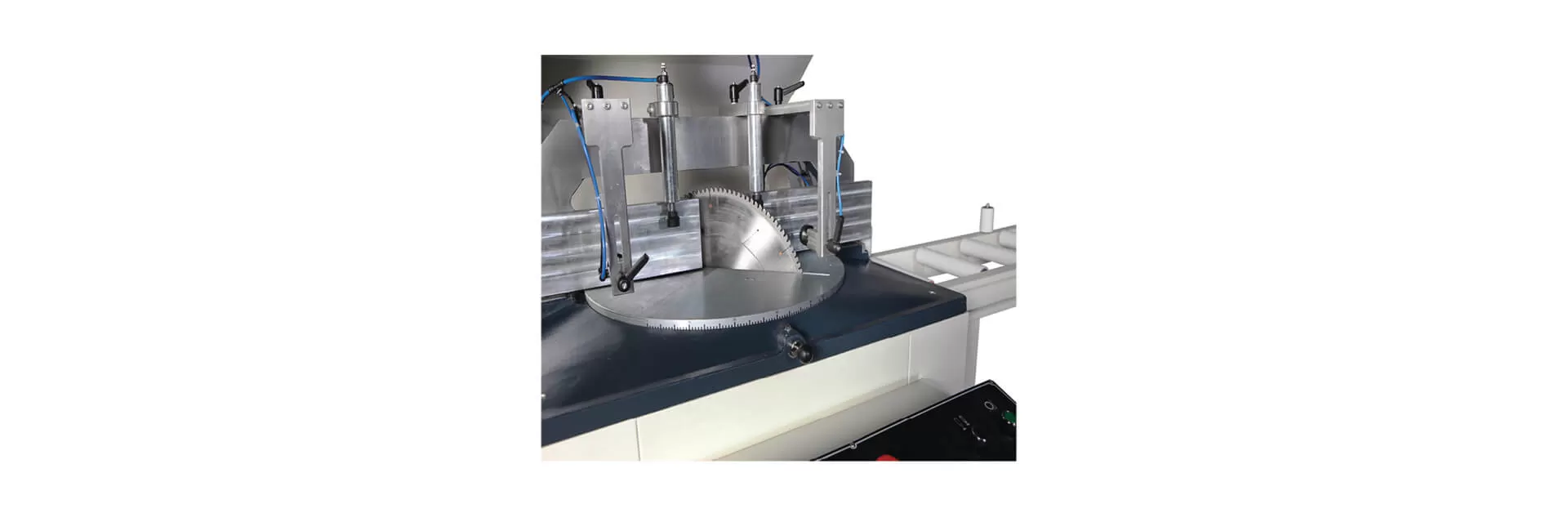

Пила 450 мм.

Пильный двигатель 1,5 кВт 2800 об/мин.

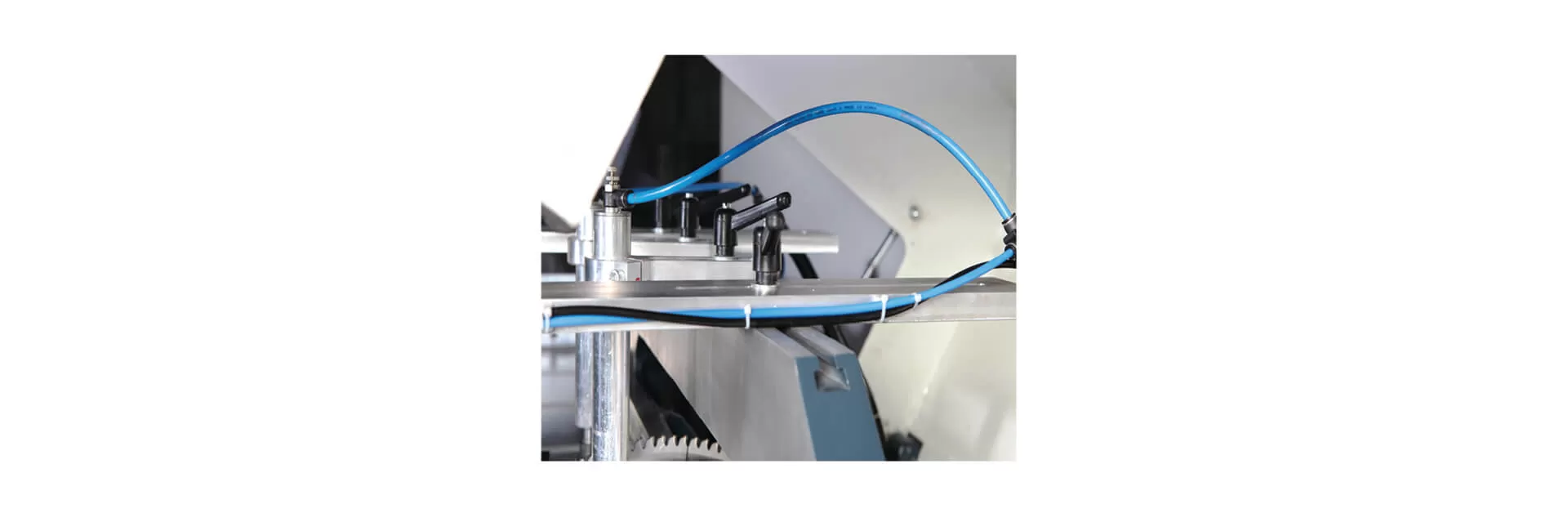

Автоматическое охлаждение пилы с помощью блока смазки распылением.

Механизм пилы, выходящий из днища.

Защитная крышка с ручным перемещением.

Группа сжатия профилей, состоящая из двух вертикальных поршней.

3,0-метровая измерительная система и подающий конвейер 3,0 метра.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

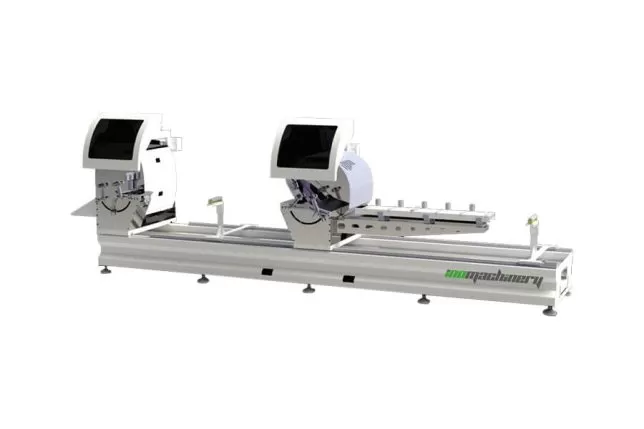

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв