AS 489 – Automatic Cutting Saw with Pneumatic Feed

Product Properties

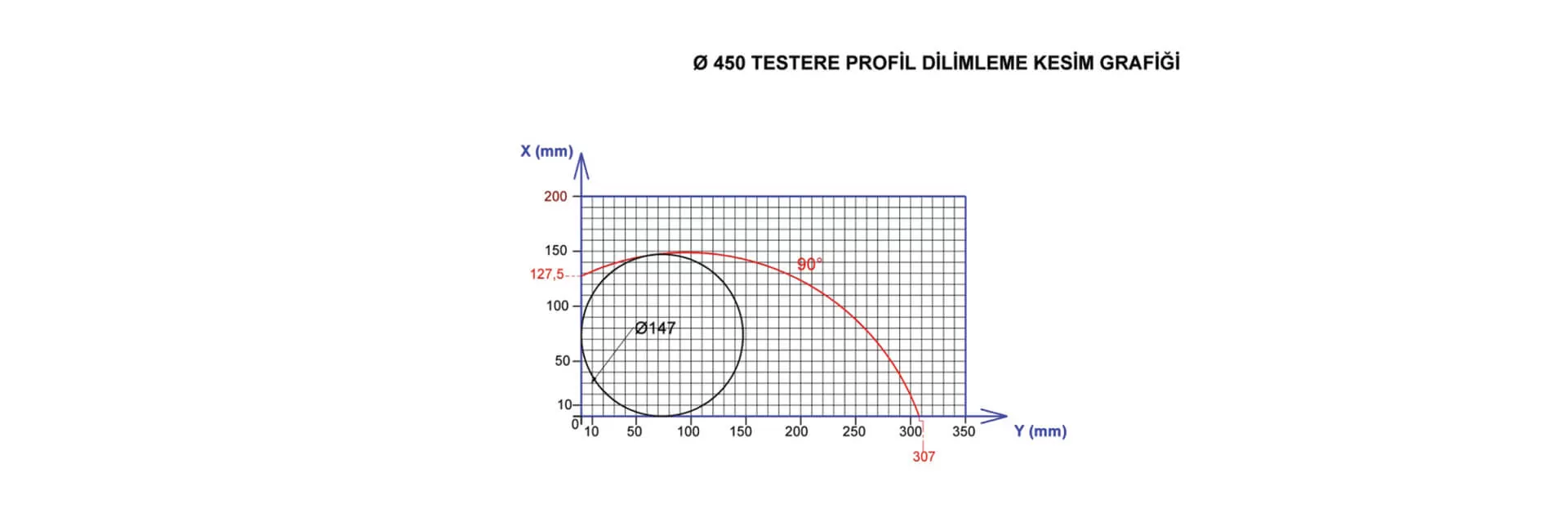

It is a compact wedge slicing machine specially designed for slicing door window profiles and industrial profiles with a 450 mm saw coming out of the bottom.

It is manually programmed with pneumatic piston and switch mechanisms in sizes between 0-300 mm and performs the cutting process by automatically feeding the loaded profiles in a length of 6 meters.

There is a scale on the machine, the switch mechanism is brought to the desired size for automatic feeding on the scale and fixed with the help of a screw.Thanks to its 4 kW belt transfer motor, it provides a very clean cutting surface.

There is no screen on the machine, there are 4 keys and with these keys the machine is started, after the whole profile is cut, the machine stops automatically on its own.With the articulated profile clamping mechanism covering the top of the cutting saw, both the cut profile and the part are held at the same time, so parts up to 3 mm short can be cut.Again, thanks to this articulated compression system, all sawdust is thrown out of the machine very simply and without error.On the side of the profile there is a 1.5-meter infeed conveyor.

Profile Machining Software

There is a button group on the machine and the cutting program is thrown into the machine using these buttons.The short part dimensions to be cut are entered manually using the scale on the machine body, the cutting is made, the cut stops automatically when a length profile is finished.

Main Body

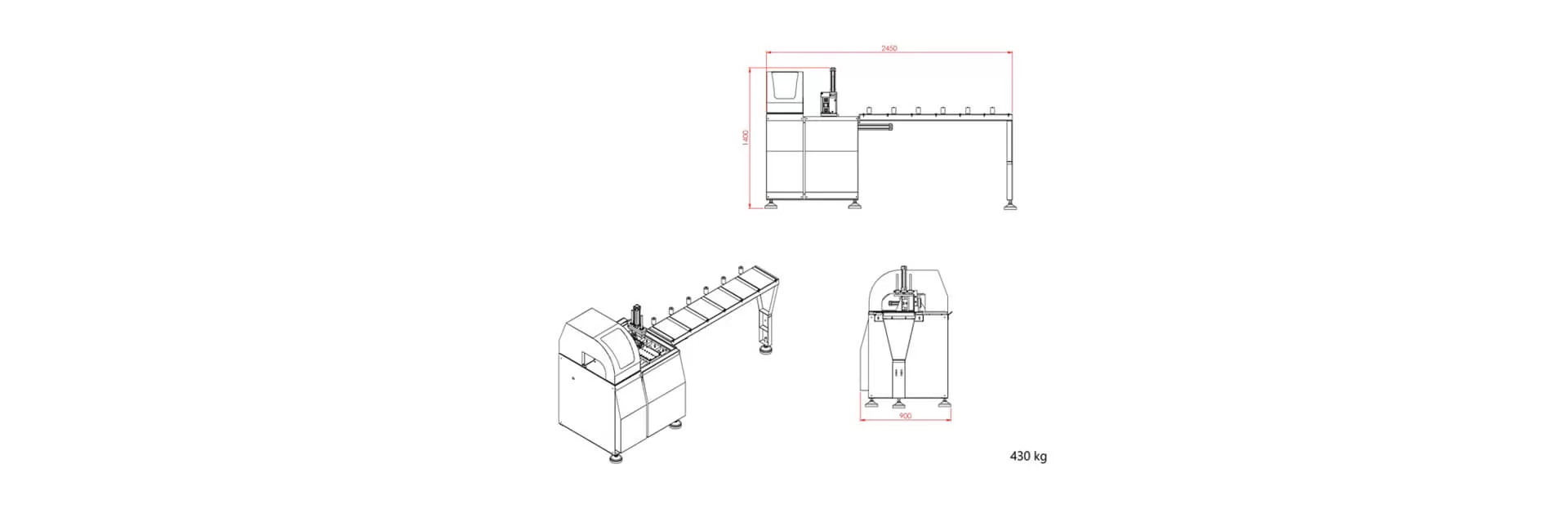

Welded steel frame normalized by heat treatment.The main body of the machine is machined in the 5-Axis CNC Steel Machining Center.

The entire body is painted with electrostatic powder paint.

Mostly all mechanical parts are machined in our own cnc machining centers or machined on cast material.During design, our design team prioritizes the operators’ease of use and ergonomics of the machines.

In the mechanical structure, not only steel and aluminum are used; at the same time, fiberglass casting parts are also used to reduce the weight of the processing bridge and give the machine a more aesthetic appearance.

Axis features

The profile pusher mechanism is driven by a pneumatic piston.

There is a scale on the driver’s side, and the cutting distance is achieved by manually positioning the sv on the scale.When the machine is started, the pneumatic piston pushes the part up to the switch, returns after hitting it, while the saw cuts the profile.

Standard Equipment

Control keypad consisting of manual buttons.

PLC Control system and manual control.

450 mm saw.4.0 kW 3,000 rpm saw motor.

Automatic cooling of the saw with a spray lubrication unit.

The saw mechanism that comes out of the bottom.

Protection cover with manual movement.

Profile compression group consisting of horizontal and vertical profile compression units and articulated saw-top printing system.

1.5 meter hopper.

Related Products

Display AllCNC

MACHINE

TECHNOLOGIES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review