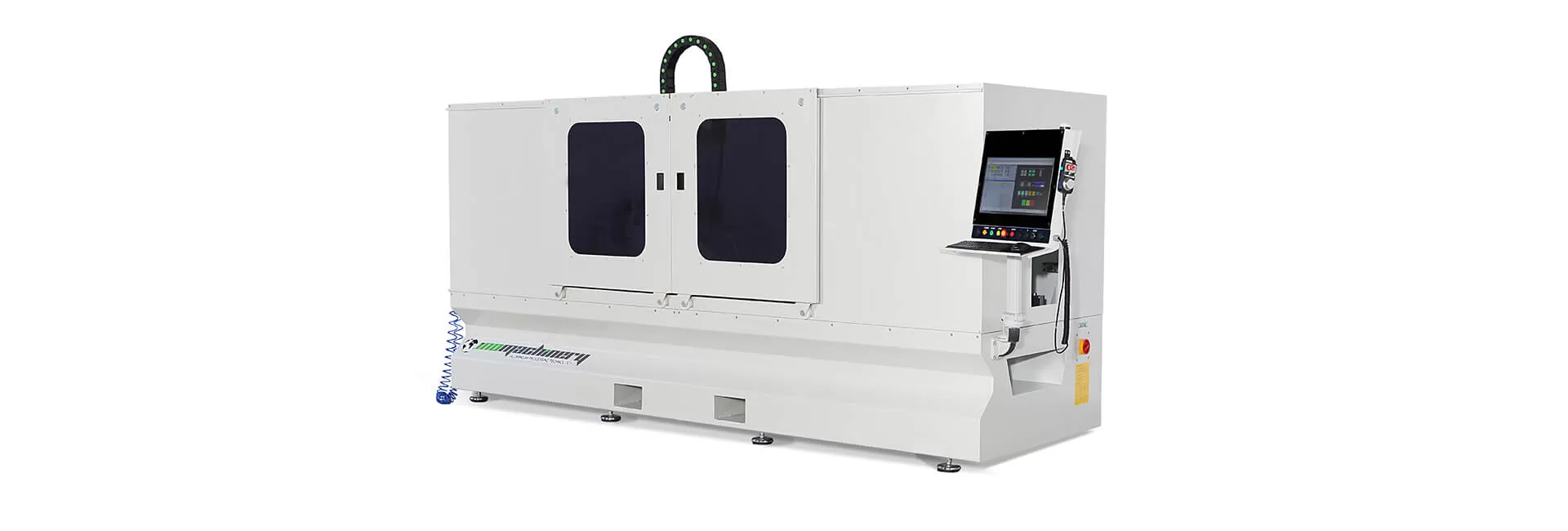

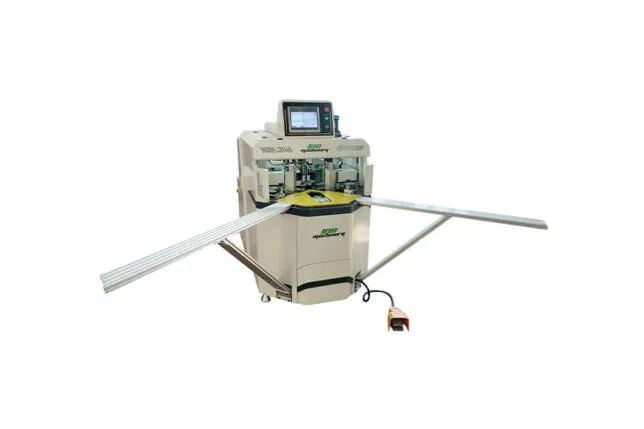

INO Boxter (XC 1000) 3 1 Ось CNC профиль обрабатывающий центр

Product Properties

Это экономичный дизайн шкафа с ЧПУ профиля обрабатывающий центр, который движется по оси X-Y-Z.

Он может обрабатывать алюминиевые и ПВХ профили.

Он специально разработан для дверных и оконных профилей.

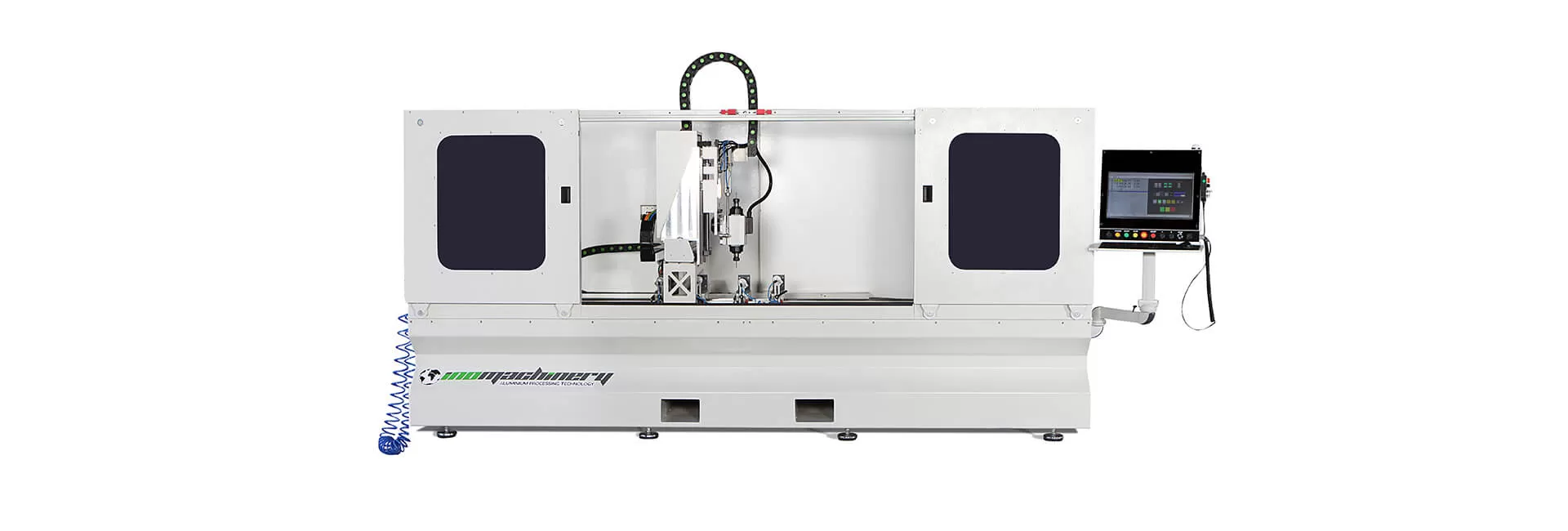

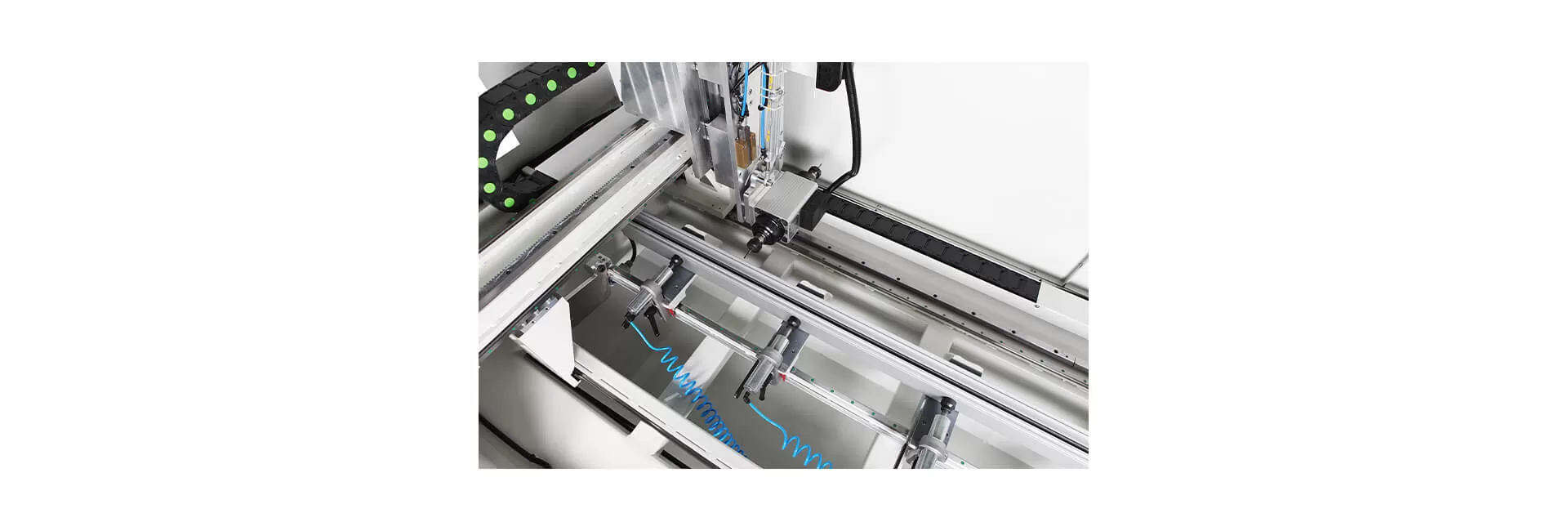

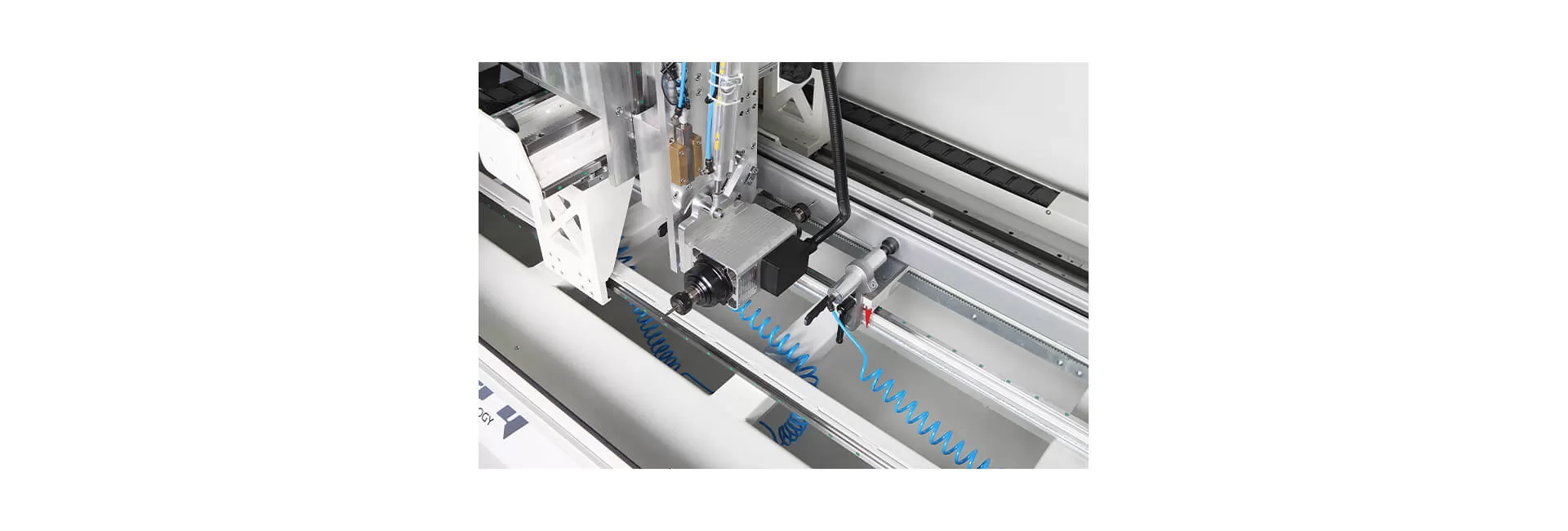

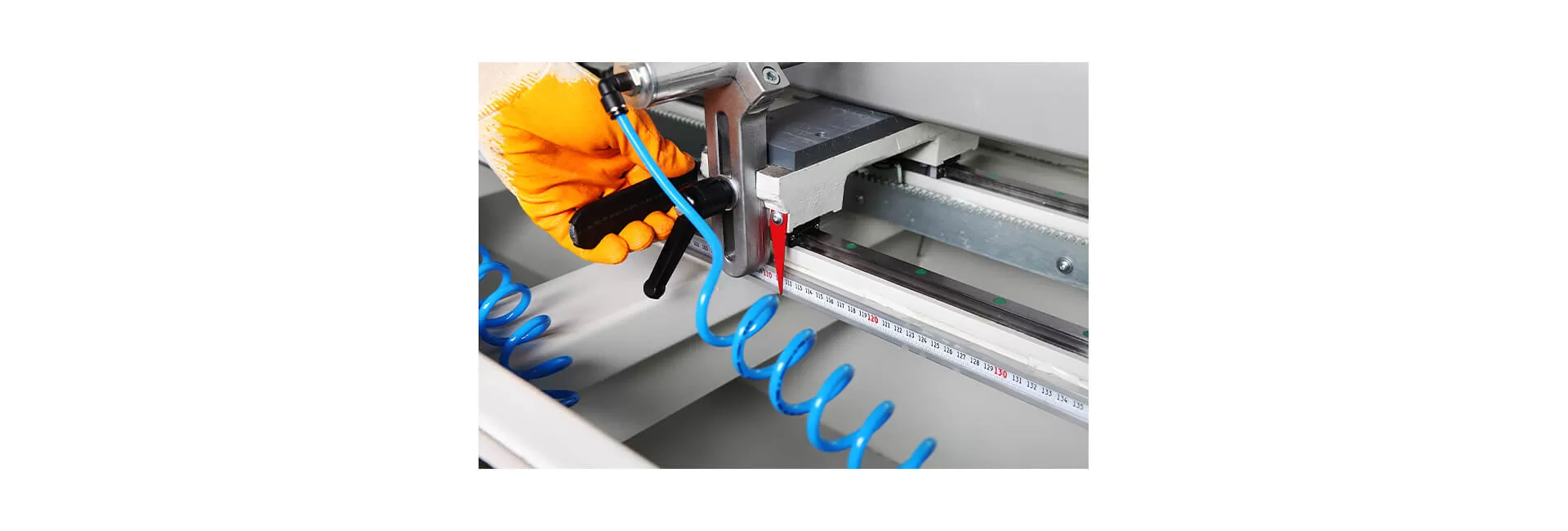

Он свободно работает на профилях с быстрой фрезерной головкой, движущейся по стальному корпусу, оснащенному блоком управления с ЧПУ и сервомотором. Опорная точка в начале и в конце станка удаляется вручную и определяет нулевую точку профилей.

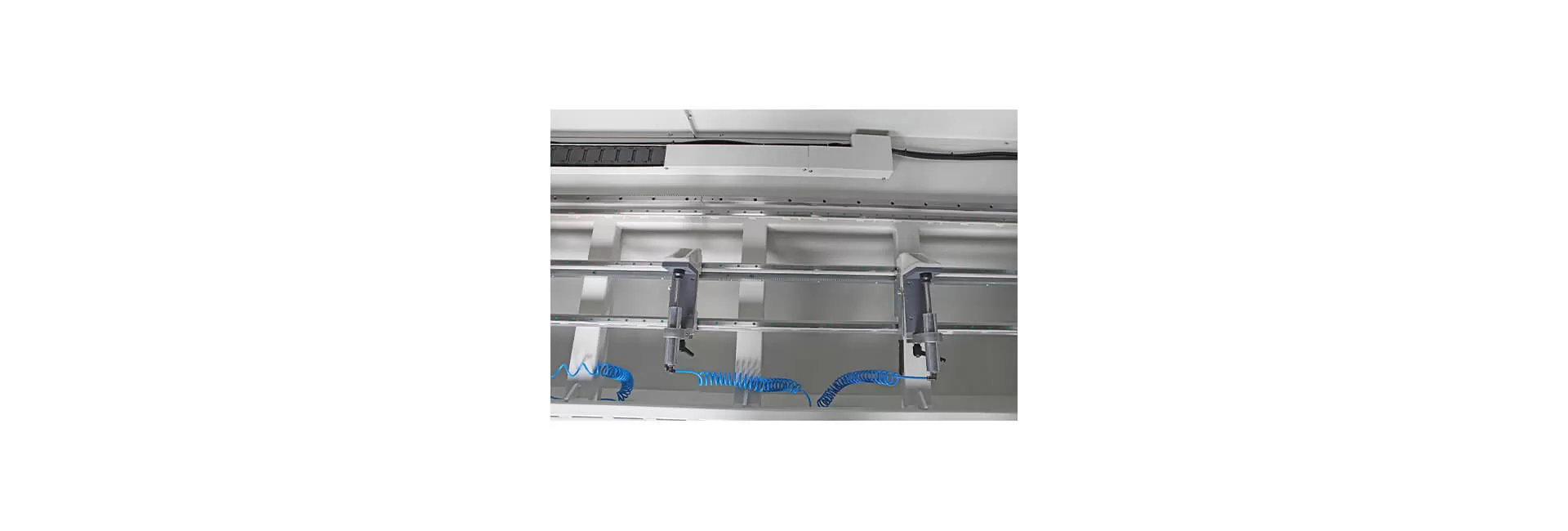

Пневматические зажимы для зажима профиля предлагаются в стандартной комплектации в 4 шт. Места нахождения пороков определяются программным обеспечением обработки профиля и представляются оператору на дисплее.

Защитная крышка перед кабиной оператора при обработке профилей закрывается вручную и открывается вручную по завершении процесса.

Profile Machining Software

Она работает с программным обеспечением, специально предназначенным для изготовления дверей и окон, и вся информация о положении зажимов, ориентации и профиле отображается оператору через свой интерфейс.

Программа позволяет импортировать чертежи двери и оконного профиля в формате dxf. При этом вводится размер обрабатываемого профиля двери, в макросах выбирается тип петли, блокировка, а обрабатываемая программа распечатывается и отображается в интерфейсе программы. При изменении длин профилей программа параметрически размещает одни и те же операции на разных длинах, подготавливает файл программы обработки, выполняя все вычисления самостоятельно.

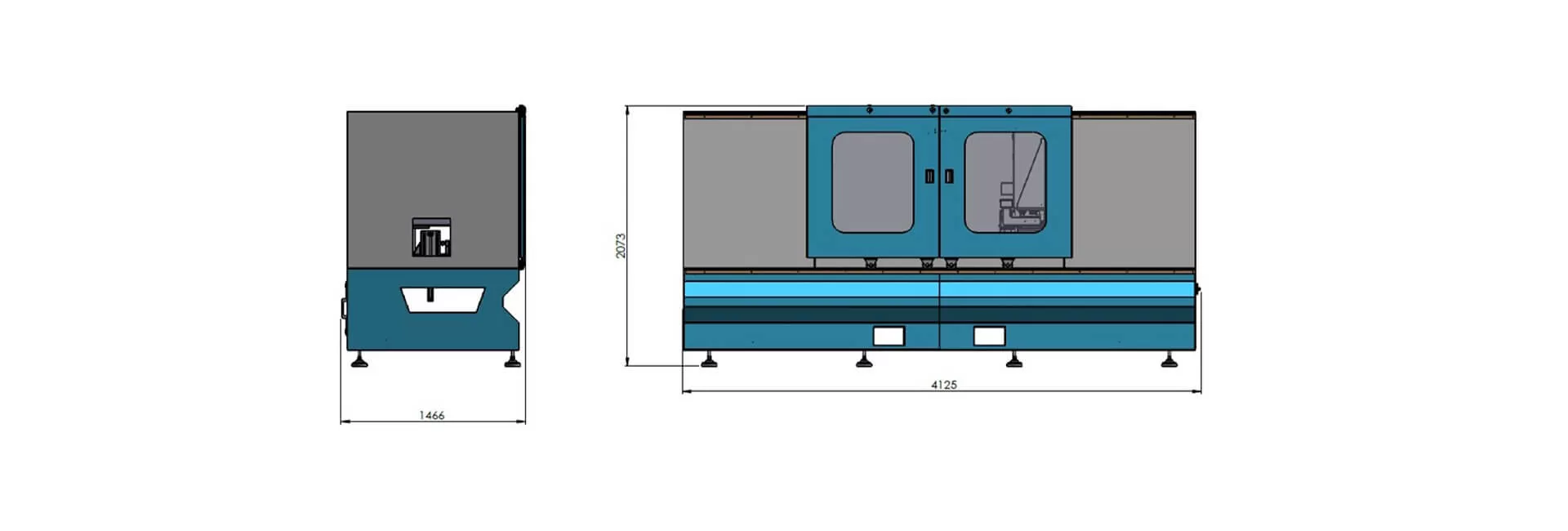

Machining Dimensions

Длина обработки профиля составляет 3000 мм, с помощью второго боллара можно обрабатывать профили до 6,0 метров. Размеры обработки профиля — 200 мм. X 175 мм над и после профиля; Когда требуется обработать профиль сверху, сзади и спереди, это 200 мм.X175 мм. В рамках этих размеров промышленные профили, которые привлекают все виды профилей или мебельных секторов, могут быть обработаны в алюминиевых дверных и фасадных производствах, от складных, скользящих до пергольных профилей.

Main Body

Сварной стальной каркас, нормализованный путем тепловой обработки.

Основной корпус машины подвергается механической обработке в 5-осевом обрабатывающем центре с ЧПУ.

Все тело окрашено электростатической порошковой краской.

В основном все механические детали обрабатываются в наших собственных обрабатывающих центрах с ЧПУ или обрабатываются на литом материале.

В процессе проектирования наша команда дизайнеров придает первостепенное значение простоте использования и эргономичности машин операторов. В механической структуре используются не только сталь и алюминий; в то же время детали из стекловолокна также используются для уменьшения веса обрабатывающего моста и придания машине более эстетического вида.

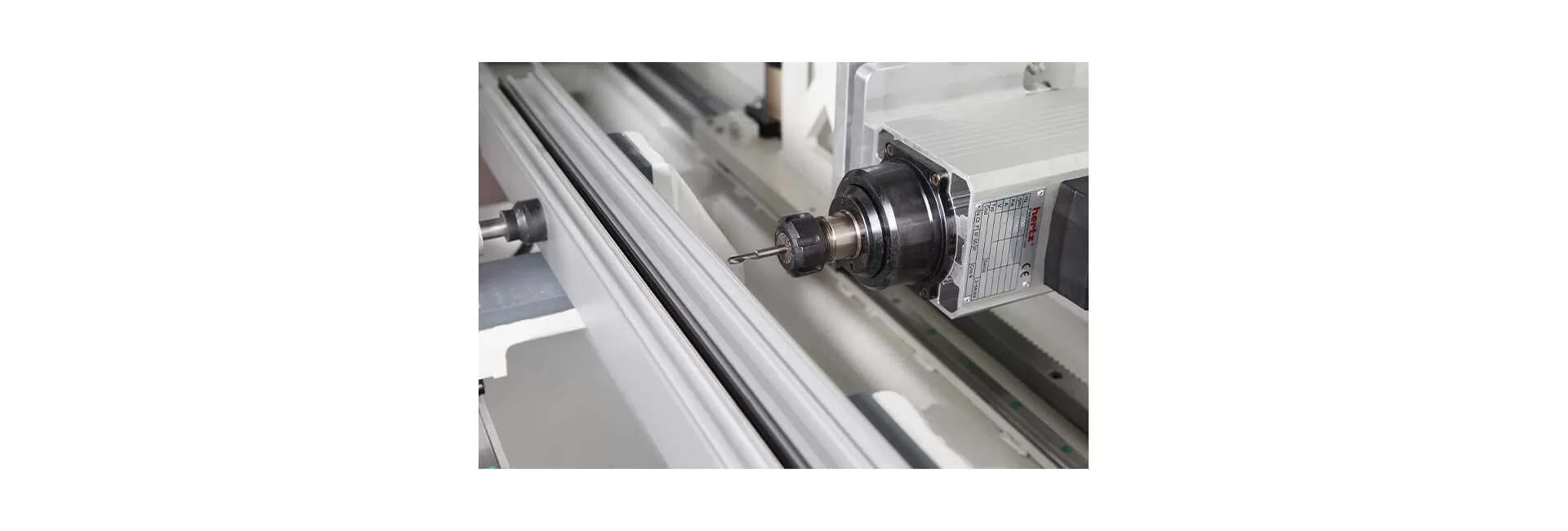

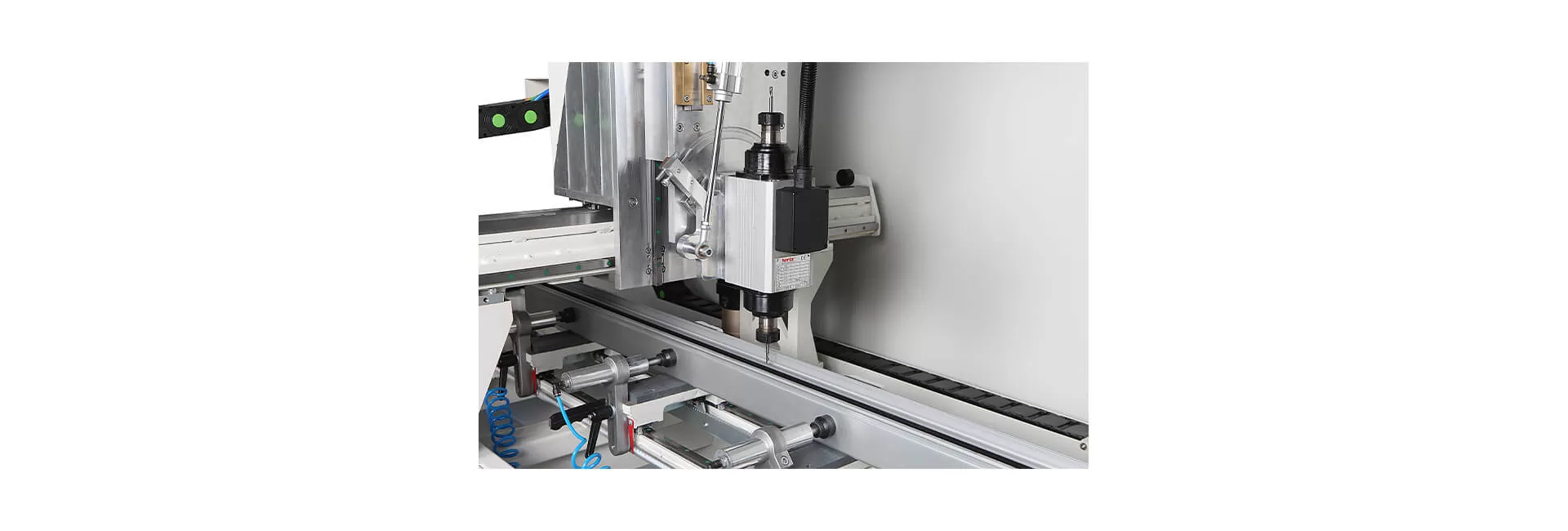

Spindles

Он оснащен уникальным двунаправленным шпиндельным рабочим устройством Ино. Быстрофрезерная головка работает при 3,0 кВт 12 000 об/мин с держателем инструмента типа ER 20 и предназначена для работы как в горизонтальном, так и в вертикальном направлении, а также под заданным фиксированным углом. Шпиндель работает профиль сверху при вертикальном положении головки, наклоняется в сторону с помощью пневматического поршня и обрабатывает профили, а при помощи специального переключателя активируется на заданном промежуточном уровне и выполняет операции при этой промежуточной степени. Благодаря программе Uni_Link она очень просто выполняет операции со всеми видами профилей в пределах размеров обработки, особенно с профилями дверей и окон.

Electrical Box and Controller Terminal

Электрическая панель встроена в машину.

Он охлаждается с принудительным вентилятором в стандартной комплектации и может опционально охлаждаться сборкой ковров для жаркого климата.

Терминал управления соединен со стороной машины. На управляющем терминале имеется дисплей Industrial PC, кнопка включения/выключения машины, кнопки перемещения осей +/- , потенциометрические кнопки, которые управляют скоростью движения машины, а также клавиатура и мышь.

Axis features

С помощью X-оси Servo Motor и Planetary Reducer, крем-движение на зубах, шестерни и линейные горки. Скорость оси 60 м./мин. С помощью Y-оси сервомотора и планетарного редуктора, движение кравели на протекторе, шестерне и линейные горки. Скорость оси 60 м./минОсь Z движется по шнековому валу. Скорость по оси 25 м./мин.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв