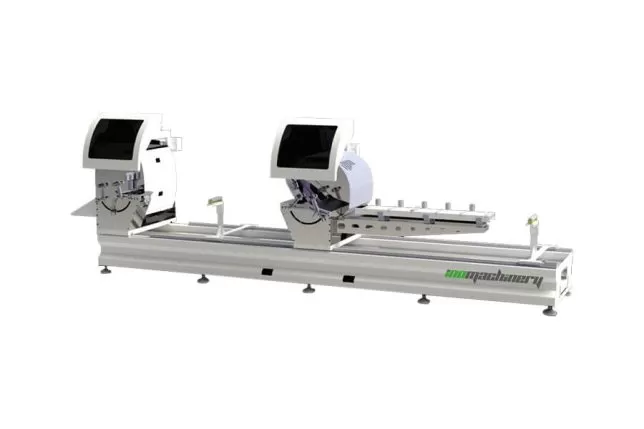

Центр обработки профилей CNC для INO XP 7000 3 Axis

ALU

3 ОСЬОбрабатывающий центр с ЧПУ типа моста

3 оси CNC профиля обрабатывающий центр для Alu профилей. С автоматическим позиционированием держателей профиля и регулировкой шпинделя 9квт 0-24.000 об/мин. Суитибле для унитисед профилей ненесущих стен, автомобильной промышленности и много вида профилирования что требует предельной точности.

Product Properties

Центр обработки алюминиевых профилей с ЧПУ типа моста

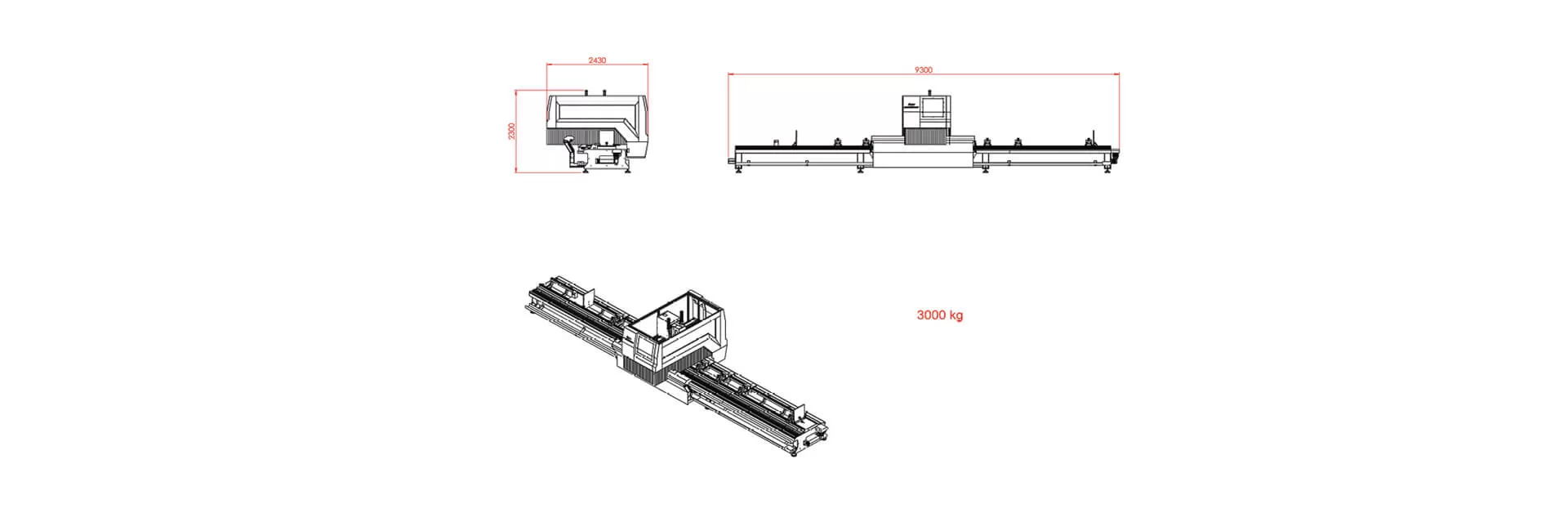

XP 7000 — это наш обрабатывающий центр с ЧПУ по оси 3+1 с обрабатываемой областью 7,000 мм.

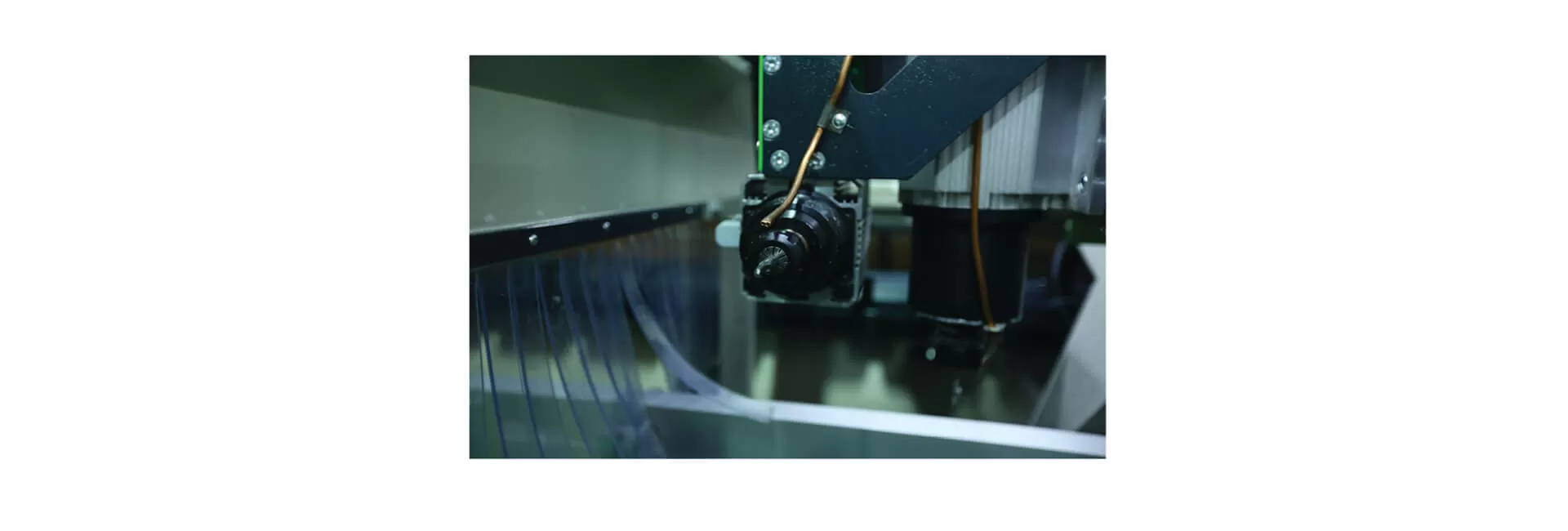

Благодаря своей высоте обработки и ширине 450 мм. х 300 мм., он может использоваться для обработки всех видов алюминиевых профилей. Это движущийся центр обработки профилей с ЧПУ на осях X-Y-Z. Мостовая система, несущая фрезерную головку, перемещается с редуцированным сервомотором и составляет 0,1 мм. / 1 мм. чувствителен. Фрезерный мотор вращается с высокой мощностью 24 000 оборотов и способен обрабатывать даже самые толстые алюминиевые профили.

Самым большим преимуществом обрабатывающего центра с ЧПУ XP 7000 является то, что он удваивает пропускную способность и мощность, которые можно получить от станка с ЧПУ благодаря работе с двумя станциями. Кроме того, тот факт, что он может обрабатывать алюминиевые профили в самом широком диаметре — размеры добавляет различное значение к продукту. Благодаря своей большой мощности обработки профиля, Ino Makine Ino XP 7000 является очень экономичным решением со своей скоростью и точностью как для компаний, которые обрабатывают фасадные профили столярных работ, так и для компаний, которые обрабатывают промышленные профили.

В промышленном типе тяжелых промышленных профилей, с его сильной структурой кузова, он может поднимать 4-5 мм стружки до толстых вяленых профилей сразу, войдя в проход, экономя время для пользователя.

Система управления с ЧПУ и оси, движущиеся с помощью высокоточных бесщеточных серводвигателей, работают в полной гармонии друг с другом, обеспечивая точность в одну десятую миллиметра на метр.

С программой обработки профиля, будь то файл шага или файл IGS, он может читать проекты от команды промышленного дизайна в 3D-форме, не вкладывая их в любой конвертер и помогает обрабатывать их в минимальное время с автоматической оснастки вариант.

Благодаря 450-миллиметровой рабочей площади по оси Y, он может обрабатывать даже большие солнечные выключатели в фасадном секторе, в то время как с промышленной стороны он выполняет все операции по бурению отверстий на самых широких вентиляционных каналах или совместных профилях без сбоев.

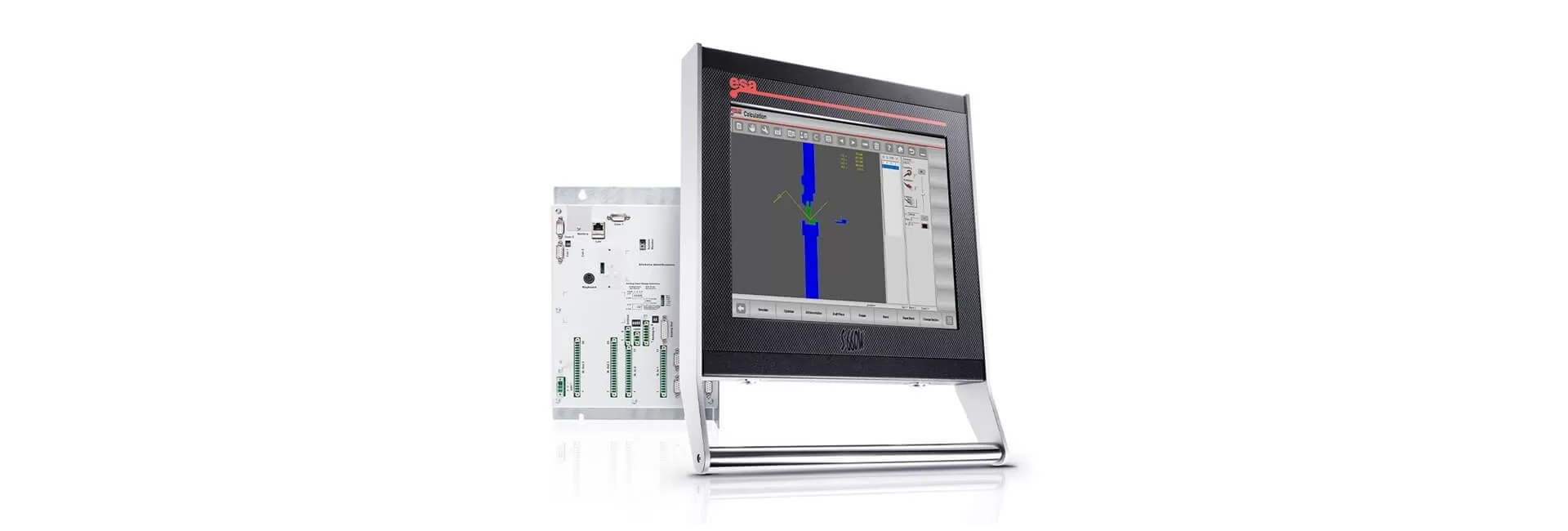

Profile Machining Software

Он работает с настроенным программным обеспечением для обработки профилей.

Благодаря программе обработки профилей чертежи dxf обрабатываемых профилей импортируются оператором и отображаются в 3D на экране, размер обрабатываемого профиля вводится, каждое отверстие или слот или свободная фигура записывается как макрос, затем эти макросы вводятся как операции, которые должны выполняться над профилем; макросы выбираются и помещаются в профиль.

В случае одинаковых операций в разных профилях программное обеспечение параметрически размещает одни и те же операции на профилях разных размеров и размеров, подготавливает программу обработки, производя все расчеты самостоятельно и может показывать эти операции с экрана моделирования. В этом списке перечислены выполняющиеся программы обработки, ориентация профиля, 3D-изображение, высота, операции, информация о клиенте и т.д. Оператор запускает машину, выбирая следующую операцию из списка.

Программное обеспечение для обработки профиля разработано и разработано таким образом, что минимальная работа остается за оператором. В офисной версии техник, работающий в офисе, может легко подготовить процессы, как если бы он находится рядом с машиной, и увидеть их на симуляционном экране, не только подготовить программы обработки, но и экспортировать информацию на режущий станок, подготовив оптимизированный список резания в соответствии с длинами резания профилей, подлежащих обработке.

Он извлекает штрих-код из режущего станка, оператор обрабатывающего центра сканирует этот штрих-код в обрабатывающем центре и обрабатывает профиль. Дополнительно Orgadata готовит программы обработки на станках, импортируя информацию из Schücal ReynaPRO и аналогичного программного обеспечения. Получив дополнительные лицензии на различные машины внутри предприятия, эти программы обработки могут работать и совместно использоваться на других машинах независимо от их марки.

Main Body

Сварная стальная рама, нормализованная термической обработкой.

Основной корпус машины обрабатывается в 5-осевом обрабатывающем центре с ЧПУ.

Весь корпус окрашен электростатической порошковой краской.

В основном все механические детали обрабатываются в наших собственных обрабатывающих центрах с ЧПУ или обрабатываются на литой материал.

В процессе проектирования наша команда проектировщиков уделяет первостепенное внимание простоте использования и эргономичности машин операторов.

В механической конструкции используются не только сталь и алюминий; в то же время детали для литья стекловолокна также используются для уменьшения веса технологического моста и придания машине более эстетического вида.

Spindles

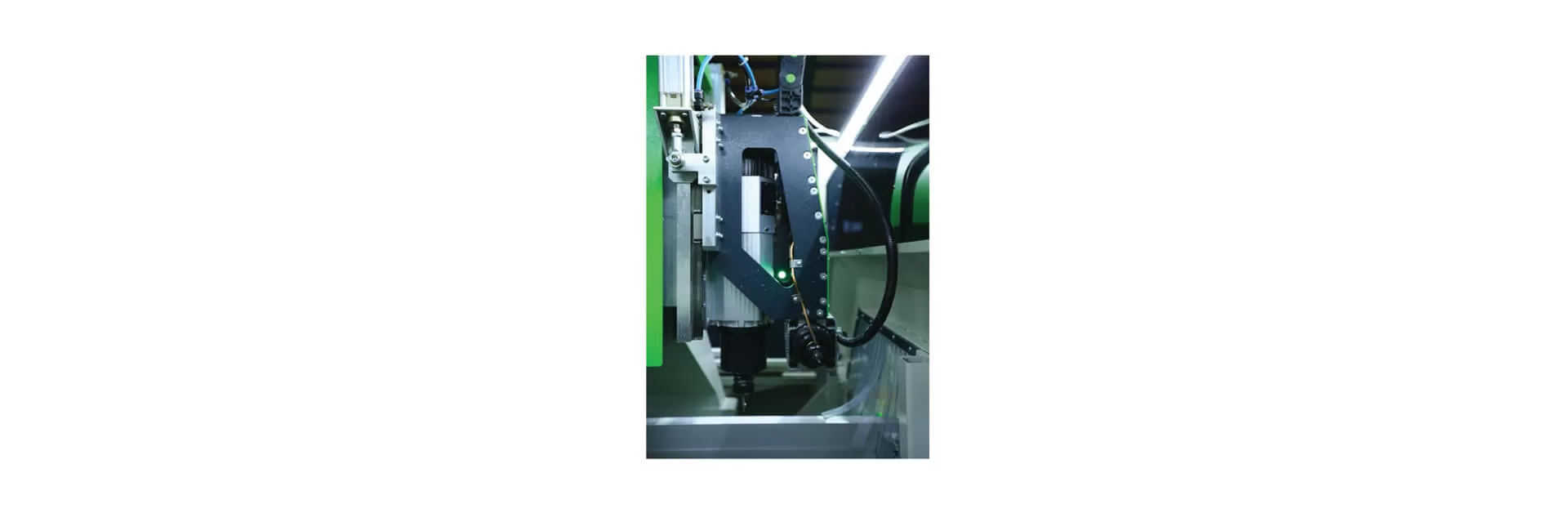

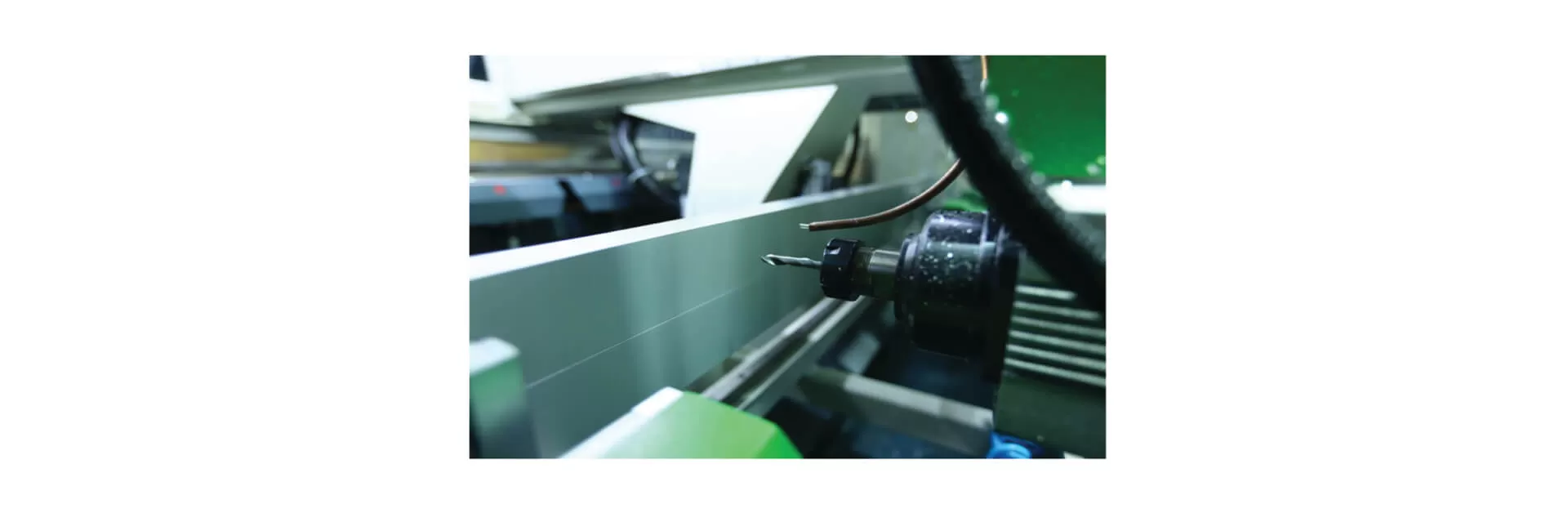

Она оснащена двухшпиндельным рабочим устройством, уникальным для Ino. Одна сверхскоростная фрезерная головка работает на 7,5 кВт 24 000 об/мин с держателем инструмента ISO30 и имеет магазин смены 8 инструментов. Дополнительная вторая фрезерная головка работает на 3,0 кВт 18 000 об/мин с держателем инструмента типа ER 20 и расположена горизонтально и стоит перед другой головкой; В случае обработки со стороны профилей, эта фрезерная головка работает. Опционально, шпиндель 24 000 об/мин с 8,5 к W HSK F-63 держатель инструмента также может быть подключен.

Electrical Box and Controller Terminal

Электрическая панель расположена отдельно от машины на колесах.

Он имеет принудительное вентиляторное охлаждение в стандартной комплектации и может быть охлажден сборкой ковров для горячего климата.

Терминал управления также выполнен в виде отдельного киоска, он соединен с электрической панелью 5-метровым кабелем. Терминал управления также колесный и может располагаться в наиболее удобном для оператора месте вокруг машины.

Благодаря этому позиционированию оператор может легко достичь каждой точки станка и может следовать за машиной из любой точки во время обработки.

На управляющем терминале имеется Промышленный ПК и его дисплей, кнопка включения/выключения станка, кнопки перемещения осей +/- , потенциометр кнопки управления темпом выполнения станка, а также клавиатура и мышь.

Standard Equipment

Две пневматические точки отсчета.

Пневматические тиски с ручным позиционированием.

7,5 квт 24 000 об/мин шпинделя ISO 30 и 8-пакетный магазин для замены инструментов.

Смазка осевых подшипников.

Программное обеспечение 3D CAD-CAM.

19-дюймовый сенсорный Intel PC + лицензированная Windows 10.

Optional Accessories

Автоматическое позиционирование пневматических вентиляционных отверстий.

Фрезерный диск 300 мм.8.5 кВт 24 000 об/мин HSKF-63 держатель шпинделя.

8 комплектов держателей для инструментов, плоскогубцев и ножей.

Передача информации из оконных программ (Orgadata и т.д.) со считывателем штрих-кодов.

Конвейер для эвакуации стружки.

Дополнительное пневматическое тиски. Электрический кондиционер шкафа.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв