INO XP 9000 5 оси CNC профиль обрабатывающий центр

Product Properties

INO XP 9000 является настоящим 5 оси CNC Профиль обрабатывающий центр работает на оси X-Y-Z-A-C независимо.

Благодаря ЧПУ-контроллеру можно выполнять любые операции трассировки, сверления, фрезерования, просеивания и резки на деталях профиля под любым углом и в любом положении.

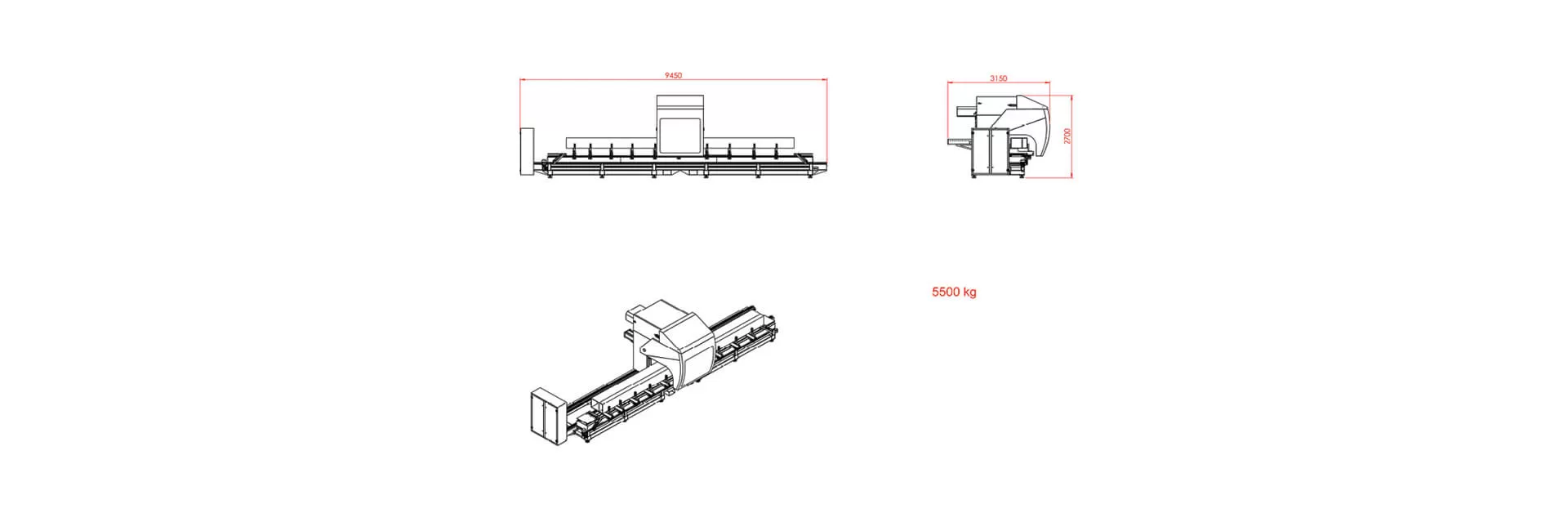

Машина имеет стандартный размер 7,5 метров и, возможно, 9,5 метров и 11,2 метров. Пневматические зажимы держателей профиля перемещаются самой колонкой С и расположены в соответствии с помещенными, которые считываются от программного обеспечения обработки профиля для предотвращения столкновения и для лучшего сцепления детали профиля.

Двухшпиндельная головка может наклоняться в оси A +/- 180 градусов и в оси C +/- 325 градусов с шпинделем, прикрепленным 12,0 кВт 24,000 об/мин с держателями инструмента HSK-F63.

Машина имеет магазин смены инструмента 10 положений и 1 для зубоскальной и режущей лезвия. Длина лезвий, которые можно прикрепить к машине, варьируется от 120 мм до 500 мм. Благодаря зубчатой лопатке диаметром 500 мм можно выполнять фрезерование, вырубку или резку любого размера профиля.

Кроме того, на этом станке можно выполнять операции трассировки и резания под разными углами.

Особенно с помощью «Программного обеспечения для профилирования» можно перечислить все операции резки и обработки на машине и выполнять их на этой машине без необходимости в другой режущей машине.

Максимальные размеры профиля в 3-х осях 500X350 мм и в 5-ти осях 350 мм X 350 мм. На машине имеется 2 рабочих зоны для эффективного использования, которые можно дополнительно расширить до 4 различных зон.

Profile Machining Software

Он работает с настроенным программным обеспечением для обработки профилей.

Благодаря программе обработки профилей чертежи dxf обрабатываемых профилей импортируются оператором и отображаются в 3D на экране, размер обрабатываемого профиля вводится, каждое отверстие или слот или свободная фигура записывается как макрос, затем эти макросы вводятся как операции, которые должны выполняться над профилем; макросы выбираются и помещаются в профиль.

В случае одинаковых операций в различных профилях программное обеспечение параметрически размещает одни и те же операции на профилях различных размеров и размеров, подготавливает программу обработки, производя все расчеты самостоятельно и может показать эти операции с экрана имитации.В этом списке перечислены выполняющиеся программы обработки, ориентация профиля, 3D изображение, высота, операции, информация о клиенте и т.д. Оператор запускает машину, выбирая следующую операцию из списка.

В офисной версии техник, работающий в офисе, может легко подготовить процессы, как если бы он находится рядом с машиной, и увидеть их на симуляционном экране, не только подготовить программы обработки, но и экспортировать информацию на машину резки путем подготовки оптимизированного списка резания в соответствии с длинами резки профилей, подлежащих обработке. обрабатывает профиль.

Дополнительно Orgadata подготавливает программы обработки на станках, импортируя информацию из Schücal ReynaPRO и аналогичного производственного программного обеспечения.

Machining Dimensions

Длина обработки профиля составляет 7500 мм, можно поставить и обработать 2 отдельных профиля до 3500 мм на двух отдельных станциях.

Размеры профиля обработки 500 мм. X 350 мм выше и после профиля; когда требуется обрабатывать профиль сверху, сзади и спереди, это 350 мм.X350 мм.A-оси движения: +/- 185 градусов. Движение по оси C: +/- 320 градусов

Main Body

Основной корпус машины обрабатывается в 5-осевом стальном обрабатывающем центре с ЧПУ.

Весь корпус окрашен электростатической порошковой краской.

В основном все механические детали обрабатываются в наших собственных обрабатывающих центрах с ЧПУ или обрабатываются на литой материал.

В механической конструкции используются не только сталь и алюминий; в то же время детали для литья из стекловолокна также используются для уменьшения веса технологического моста и придания машине более эстетического вида.

Tool Changer Magazine

Это 9-пакетный и сервоуправляемый магазин «Линейного типа», расположенный на мостике машины.

В то время как 9 фрез находятся в одном магазине, второй магазин, интегрированный в колонку C, имеет набор пил 500. Верхняя часть магазина закрыта защитной крышкой из пневматически движущегося материала волокна.

Electrical Box and Controller Terminal

Терминал управления также выполнен как отдельный киоск, он соединен с электрической панелью 5-метровым кабелем.

Терминал управления также колесный и может быть расположен в наиболее удобном для оператора месте вокруг машины.Благодаря этому позиционированию, каждая точка машины легко доступна для оператора и может следовать за машиной из любого места во время обработки.На терминале управления есть промышленный ПК и его дисплей, кнопка включения / выключения машины, кнопки перемещения осей +/- , потенциометр кнопки, которые управляют скоростью движения машины, а также клавиатура и мышь.

Axis features

С помощью оси X серводвигатель и планетарный редуктор, движение щели на зубах, шестернях и линейных скольжениях.Скорость оси составляет 90 м./min.With помощь оси Y серводвигатель и планетарный редуктор, движение кравели на протекторе, шестерне и линейных скольжениях.Скорость оси 65 м./минОсь Z движется с 1/1 редукционной муфтой на 25-рулонном 25-шнековом вале.Скорость оси 25 м./минОсь A вращается с бесступенчатым гармоническим редуктором в соотношении 1:1 120. Ось C вращается с беспрерывным гармоническим редуктором в соотношении 1:120.

Standard Equipment

Две пневматические точки отсчета.

8 пневматических групп визави с ручным позиционированием.

12.0 кВт 24 000 об/мин HSK F-63 шпинделя и 10 блок смены инструмента магазина.

Открывайте защитную крышку машины.

Смазка распылением. Смазка осевых подшипников.

Программное обеспечение 3D CAD-CAM.

19-дюймовый ПК Intel + лицензированная Windows 10.

Optional Accessories

Автоматическое позиционирование пневматических вентиляционных отверстий.

Комплект для кертинга и держателя шпинделя HSKF-63 500 мм.17 кВт 24 000 об/мин с держателем.

10 комплектов держателей инструментов, плоскогубцев и ножей.

Передача информации из оконных программ (Orgadata и т.д.) с обработчиком штрих-кода.

Дополнительный пневматический тиски. Электрический шкаф кондиционера.

Связанные продукты

Дисплей ВсеCNC

МАШИНА

ТЕХНОЛОГИИ

машина профиля CNC

Ино машинное оборудование; Он разрабатывает, производит и экспортирует современные ОБРАБАТЫВАЮЩИЕ ЦЕНТРЫ ПРОФИЛЯ CNC и аналогичные технологии, которые могут выполнять обрабатывающие прецизионные обрабатывающие работы на алюминиевых профилях.

открытиеОбработка панели CNC

Наши модели обрабатывающих центров с ЧПУ производятся с превосходной технологией R&D INO Machinery, с процессами, такими как резка и затирка панелей из алюминиевых композитных материалов с высокой точностью.

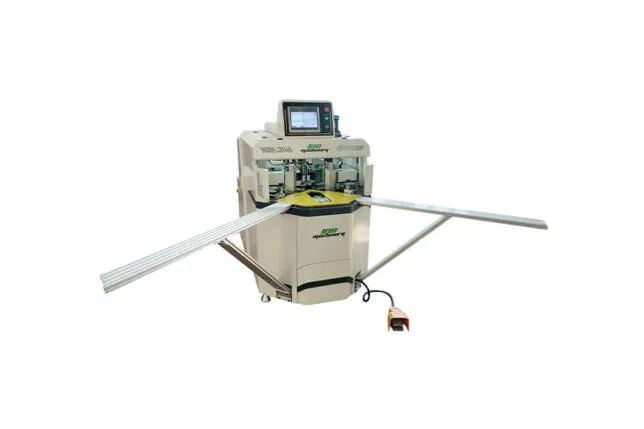

открытиеКопировать маршрутизаторы | Kонец Фрезерование

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

открытиеУгол Пресс

Наши угловые пресс-машины модели, используемые в угловой процесс соединения алюминиевых профилей, которые гарантируют плавную выравнивание и блокировки алюминиевых профилей во время прессования.

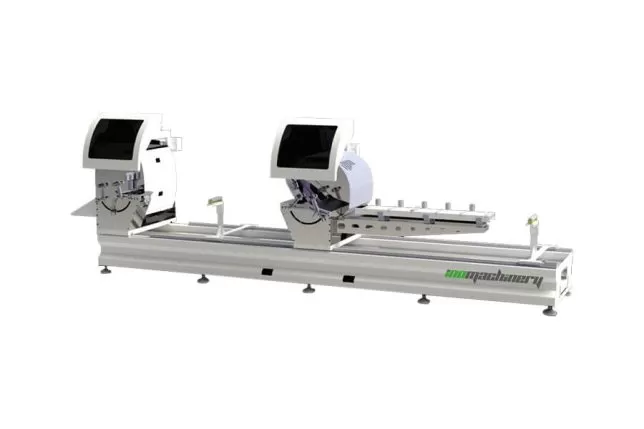

открытиеАлюминиевые профили для резки пил

Наши автоматические модели одноголовочного и двухголовочного пильного станка / режущего станка с возможностью вырезать горизонтальные или вертикальные фиксированные алюминиевые профили.

открытие

Обзоры продуктов

Рецензии пока нет.

Добавить отзыв