CNC Panel Processing

- CNC Profile Machining

- CNC Panel Processing

- Aluminum Profile Cutting Saws

- Copy Routers | End Milling

- Measurement System

- Corner Press

- All Products

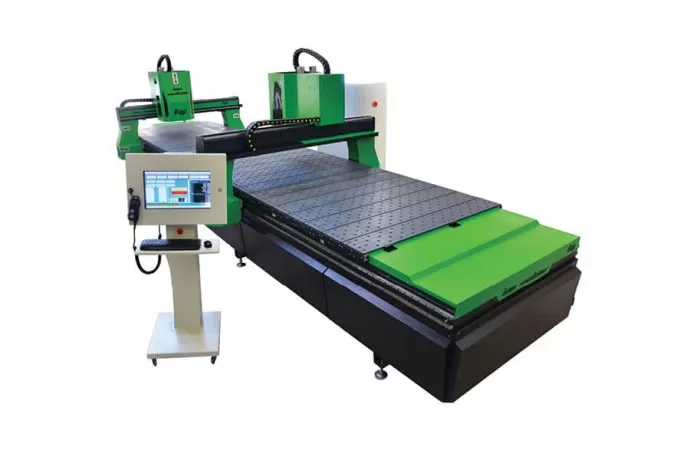

INO XX 9900 – Double Bridge CNC Panel Machining Center

More Info

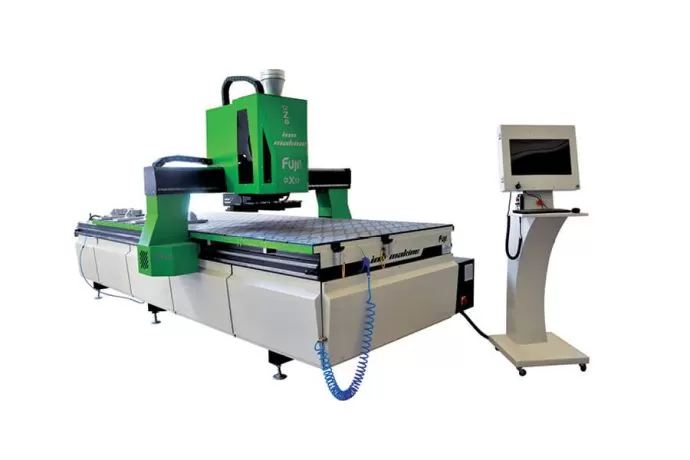

INO XQ 1665 – Double Station CNC Panel Machining Center

More Info

INO XT 1665 – Double Station CNC Panel Machining Center

More Info

INO XQ 1640 – CNC Panel Machining Center

More Info

INO XT 1640 – CNC Panel Machining Center

More InfoINO Machinery Production CNC Panel Processing Center Features

The CNC Panel Processing Machinery specialized for machining aluminium composite panels.

Also called in the market as ACP panels or ACM panels.

The dust extractor is mounted on the spindle motor, collecting nearly 100% of the dust caused by the panel and keeps the machine clean.

The surface of the panel is prevented from the scratches that may be caused by the dust dropping on the panel.

CNC panel sizing center equipped with vacuum table and milling head:

- The most efficient way to keep panel production at high speed and is available in many of our Machine models, with dual station or double bridge capability.

- The vacuum table is divided into 4 separate parts because each vacuum chamber can be controlled individually in order to process the smaller parts in the most precise way.

- Automatic vacuum opening and closing system in panel size that is treated on the machine.

- Thanks to the SMART TRAY system, according to the size of the panel that the manufacturer is processing, according to the speed of work or the thickness of the panel, all vacuum chambers and rests are CNC controlled, not left to the initiative of the operator.

- Direct management of tool movement and operation of machine components with machine operation panel or machine panel.

Machine Machined Materials:

- Aluminum Composite Panel,

- Stainless Steel Composite Panel,

- HPL Compact Laminate Panel,

- Pure Aluminum Panel up to 20 mm wall thickness,

- Acrylic Panel,

- MDF and Wood or similar panels.

Net Processing Size:

There are cnc machine models with different panel processing lengths in the range of 4.000 mm. / 10.000 mm.

Net Processing Width:

In all CNC Aluminum Composite Panel Machining and Sizing Center models, the machining width is in the range of 1.600 mm. / 2.100 mm.

Net Processing Height:

In all CNC Panel Sizing Machine models, the machining height is 300 mm.

CNC Machine Software:

Customized software for CNC Panel Sizing and Machining; CAMBOX:Macros specific to the construction sector related to composite panels and HPL (Compact Laminate) or aluminum sheets are readily available on CAMBOX.However, in cases where this is not enough, new macros can also be created according to customer demand

CNC Tool Changer Magazine:

Pneumatic moving magazine placed under the machine bridge on most models and moving together with the machine.

Suitable for ISO30 or HSK F-63 type tools.

CNC Machine Standard Hardware:

- CNC Control for Vacuum Zones;Because with the help of the CNC control mechanism, the vacuum zones are opened and closed automatically according to the size of the plate to be processed.

- 4-10 pneumatic reference points [The number of reference points varies according to the machine model.]305 m3 vacuum pump.Lubrication of axis bearings.

- vacuum pump of 305 m3.

- Oiling of axis beds.

- 3D CAD-CAM software.

- 10″ and 15″ or 15.6″ size Touch Screen. [Screen size varies depending on machine model.

As a result, all the features mentioned above make Ino Machinery superior to its competitors. However, customer satisfaction and loyalty are the secret to our success and our approach to communication and technical support.